The Custom Mold Component Leader

Gain efficiencies by having your components come in done:

Mold-Ready™ Components utilize Progressive’s exclusive configurable part number format so that the description in the BOM is all that is needed… No prints necessary.

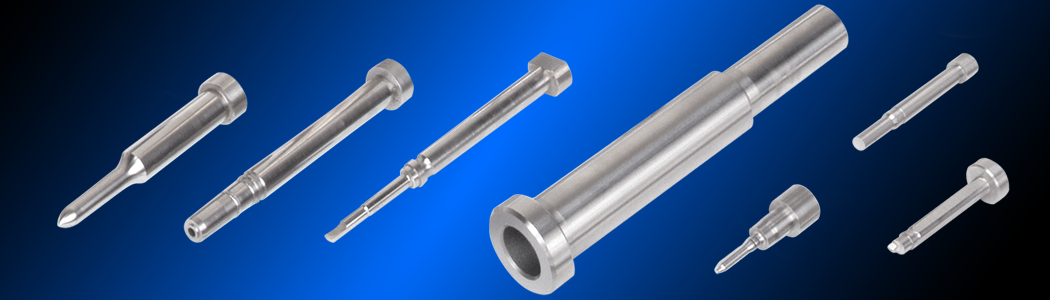

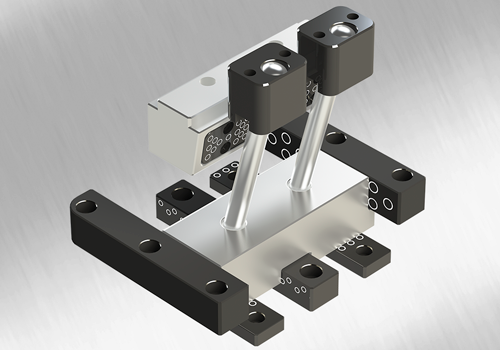

Custom Components, such as complex Pins and Sleeves, retrofitted Alignment Locks, UniLifter Core Blades, and more, can be provided per template, print, or CAD model.

If your company is sourcing custom pins or sleeves, contact Carl at 1-800-269-6653 ext. 565 or email tech@procomps.com, to request a quote from a trusted source for your demanding applications.

Made to Your Specifications.

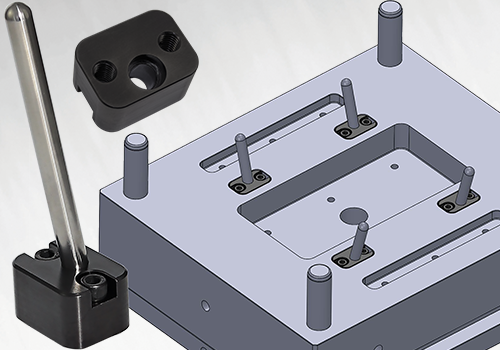

Mold-Ready™ Components… Standards That Come In Done!

Save time and money with Progressive’s Mold-Ready Components. In the mold’s Bill of Materials, designers can insert configurable part numbers, and then rather than adding straightforward details to a standard item, the mold builder’s time can be focused towards more complex cavity and core work.

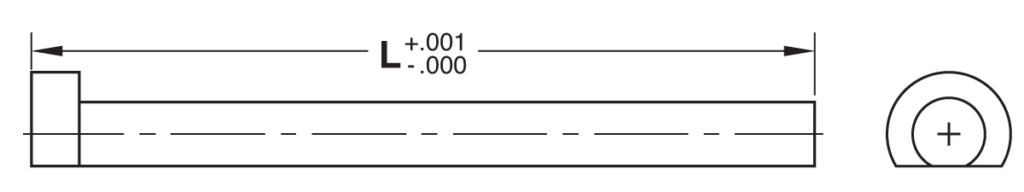

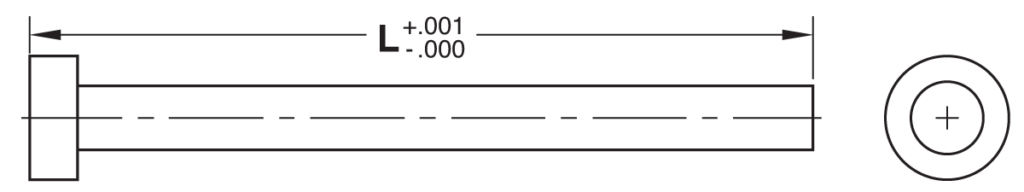

Following are examples of how to utilize configurable part numbers when ordering.

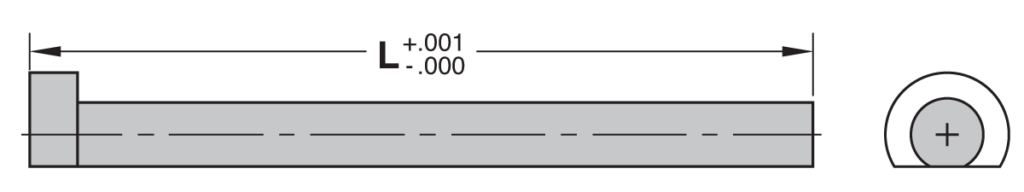

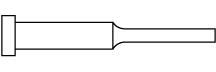

Keyed Pins: Add “-K” to Catalog #

Standard P/N: EP375L10

Mold-Ready PN: EP375L10-K

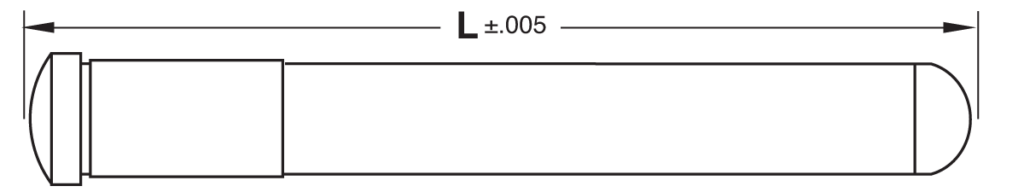

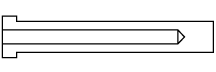

Cut-to-Length Pins

Standard P/N: EP375L10

Mold-Ready PN: EP375L9.133

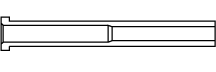

Keyed, Cut-to-Length, Black Nitride Pins

Key, Cut-to-Length, Black Nitride Pins

Standard P/N: EP375L10

Mold-Ready PN: EP375L9.133-K-BN

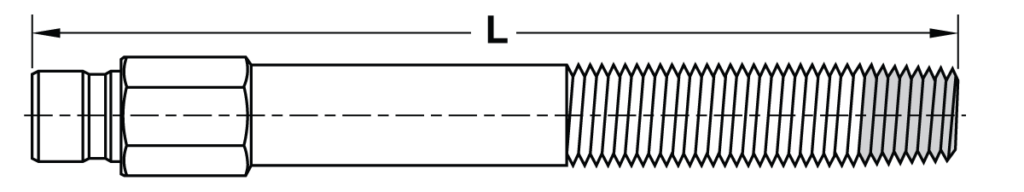

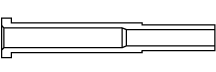

Finished Angle Pins

Standard P/N: APR625L10

Mold-Ready PN: APR625L7.244

Finished Water Fittings

Standard P/N: 352L5.5

Mold-Ready PN: 352L4.53

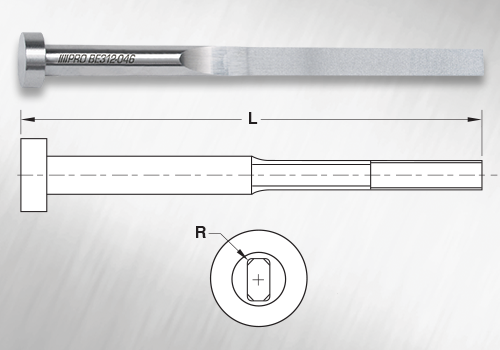

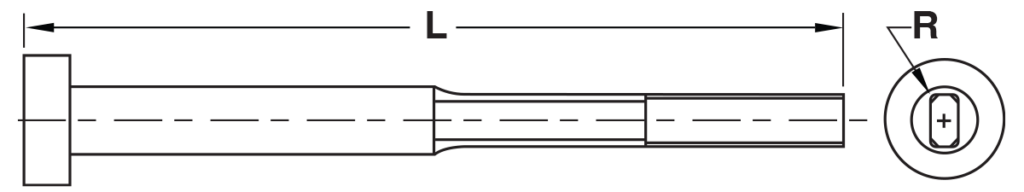

Finished Ground Blade Ejectors

Standard P/N: BE125-046L6.5

Mold-Ready PN: BE125-046L6.155-R.020

For additional details and configurable part number examples of Mold-Ready Blade Ejectors, please click HERE.

Medical and packaging molds require high quality, high tolerance core pins and sleeves, and our team is experienced in providing precision, Mold-Ready components. Customers also appreciate that Pro’s products are never Made in China.

Carl Niedorowski

Technical Product Specialist, Progressive Components

“Medical and packaging molds require high quality, high tolerance core pins and sleeves, and our team is experienced in providing precision, Mold-Ready components. Customers also appreciate that Pro’s products are never Made in China.”

Carl Niedorowski

Technical Product Specialist, Progressive Components

Technical Product Specialist

Progressive Components

In The Press

Made-to-Order Mold Components

We’ve created various ordering templates for many of our custom and special order products, which are available here.

In addition to these items, Progressive can provide alternative materials, treatments, or configurations for any standard product available in the Progressive Components catalog.

Forms are provided in Adobe Acrobat™ (.PDF) format. Download and fill out the specifications required and email to tech@procomps.com.

Angle Pins

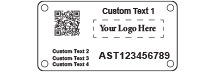

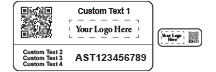

Asset Plates

Asset tags

Bar Locks

Blade Ejectors

bushings: shoulder

Core Pins: Single Step

core/ti pins: straight

Ejector Pins: Single Step

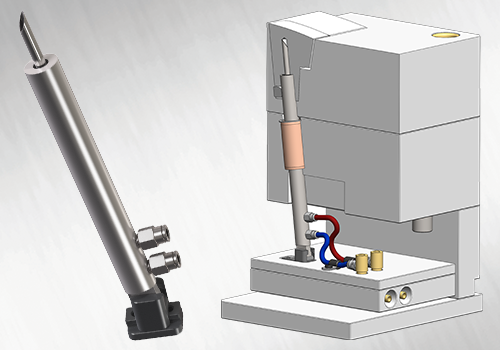

Ejector Pins: Water Cooled

Ejector Sleeves: Straight

Ejector Sleeves: Stepped

Ejector Sleeves: Thin Wall

Ext. Plugs: Finished Length

Guide Locks

leader pins: shoulder

leader pins: straight

Press Knock Out: Hex Series

Side Locks

Top Locks

UniLifter Core Blades

UniLifter Core Blades: L

UniLifter Core Blades: round

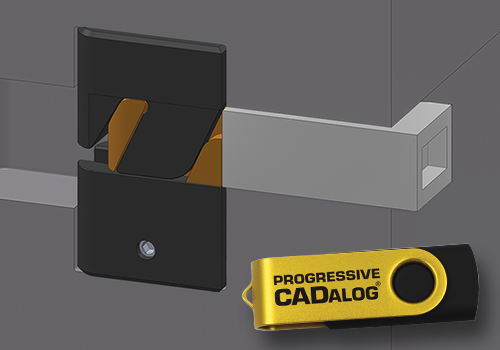

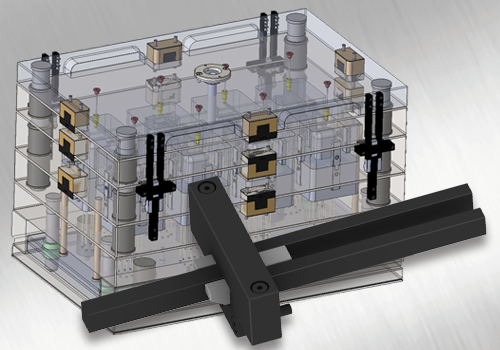

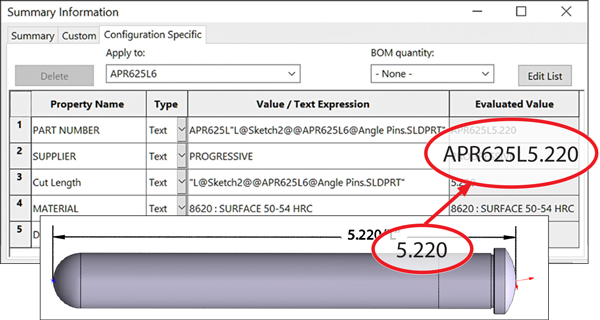

New Options for SolidWorks Users

Progressive’s CADalog® offers a SolidWorks library of configurable CAD geometry with populated attributes for ordering cut-to-length components.

Now, automatically generate Mold-Ready item numbers, then email the final BOM to Pro’s Customer Service team, to then receive the components quickly and ready for assembly.

Are you a SolidWorks user? Got questions on how to access what has been built for you? Contact us at tech@procomps.com.

Don’t yet have a CADalog? Go to procomps.com/CAD to receive geometry for SolidWorks, NX, VISI, as well as Neutral .step, .x_t, .sat, and .igs formats.

For questions and more information on Progressive’s Custom and Mold-Ready products: