PROGRESSIVE RELEASES NEW V15 CATALOG

Since Progressive’s first days, there’s been a drive to simplify design, speed mold builds, and eliminate unscheduled mold stoppages by developing innovative products that later become global industry standards.

Today, we proudly present our v15 catalog, which features new standards for greaseless and cleanroom molding, innovations to advance undercut release and plate sequencing, side action components that are serviceable in the press, and new mold monitoring advancements for OEMs, Molders, and Mold Builders.

Whether you build, buy, or run molds, accessing solutions from Pro’s catalog can only benefit your tooling programs ahead.

To request a new v15 catalog call 1-800-269-6653/1-847-487-1000 or visit procomps.com/v15.

PLASTICS NEWS BEST PLACES TO WORK 2023

Progressive is proud to have been named the 2023 Plastics News Best Places to Work runner-up. The announcement was made February 28th, at the Plastics News Executive Forum, where company owners Glenn and Don Starkey accepted the award.

“With all we have gone through in the past three years, our biggest concern is knowing that our culture is still intact. Through the PN BPTW survey, we confirmed that our ProCompers have held it together,” said Don Starkey when accepting the award crediting the company’s 70-plus employees for making this award possible.

Progressive works to have the best team in place to meet the needs of the best molders and mold builders in the industry.

Glenn Starkey added, “Our employees embrace our customer- centric culture, and with the best customers in the world, we dedicate this award to you!”

To view the lighthearted video of Don and Glenn accepting, learn more about the Plastics News Best Places to Work award (a research-driven program from Best Companies Group), view the complete list of finalist companies from 2023, information on Progressive’s employees and culture, and more, visit our website at procomps.com/BPTW.

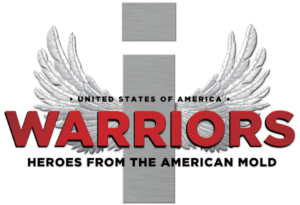

INTERNAL TOP LOCKS

To avoid water lines and other mold features, the new square Internal Top Lock mounts inboard versus at the mold base’s edge and are available in three inch and three metric sizes to provide maximum alignment with minimal space requirements.

Click HERE for additional information and online ordering.

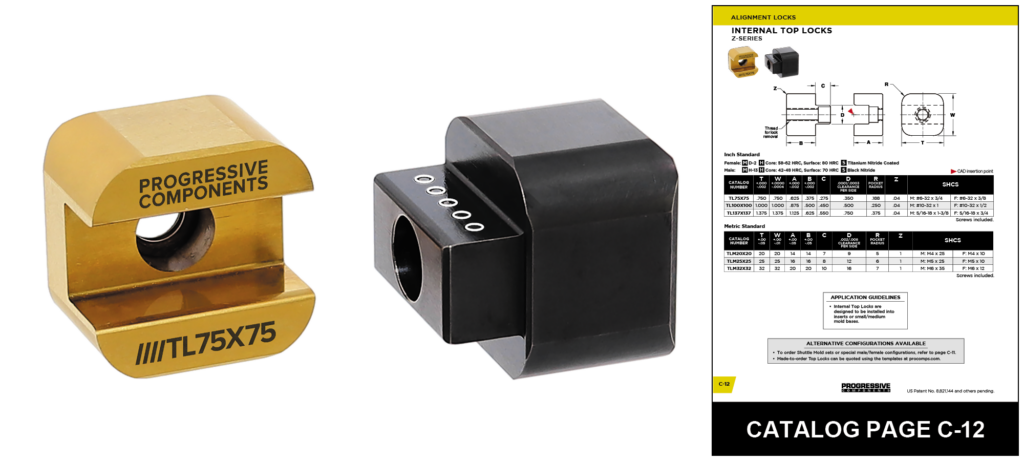

COUNTERBORED ROUND TAPER LOCKS

Mounted from the mold’s parting line, the new Counterbored Round Taper Lock is available in a range of five sizes from 1/2” to 2” diameters.

This advanced standard is the industry’s only Taper Lock featuring Progressive’s proprietary materials and treatments.

Click HERE for additional information and online ordering.

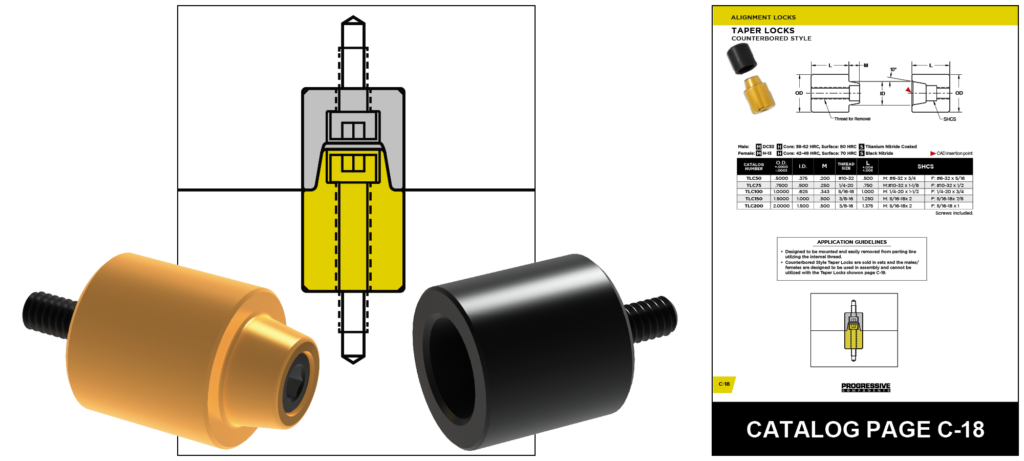

RECTANGULAR TAPER BAR LOCKS

Engineered to be installed and removed from the parting line, the new Rectangular Taper Bar Lock provides precision alignment with an increased alignment surface.

Sizes offered match industry standards, but performance is maximized through the utilization of Progressive’s Z-Series materials and treatments.

Click HERE for additional information and online ordering.

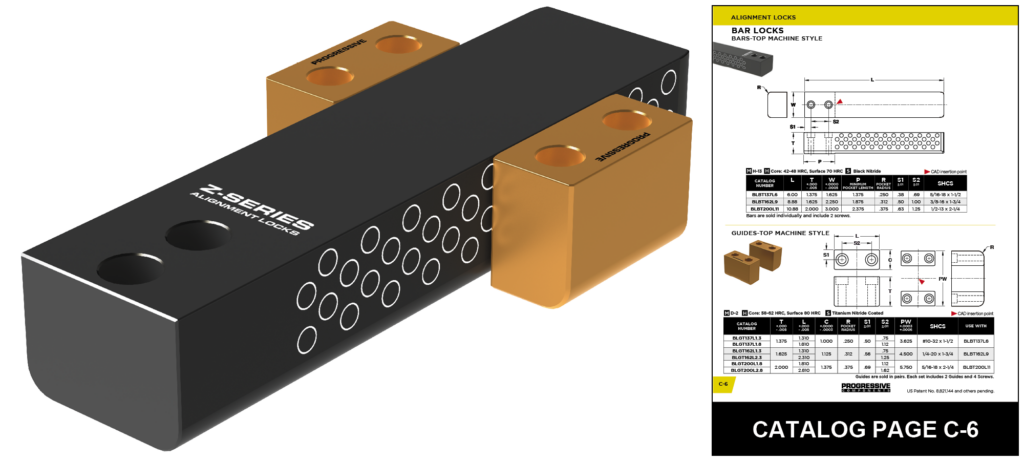

TOP MACHINE STYLE BAR LOCKS

Designed to be machined from the top at the parting line, Top Machine Bar Locks simplify machining steps and increase pocket accuracy by allowing the alignment pockets to be machined on the same setup as cavity and core plate pockets.

Top Machine Bars are available in three sizes to pair with corresponding Guides.

Click HERE for additional information and online ordering.

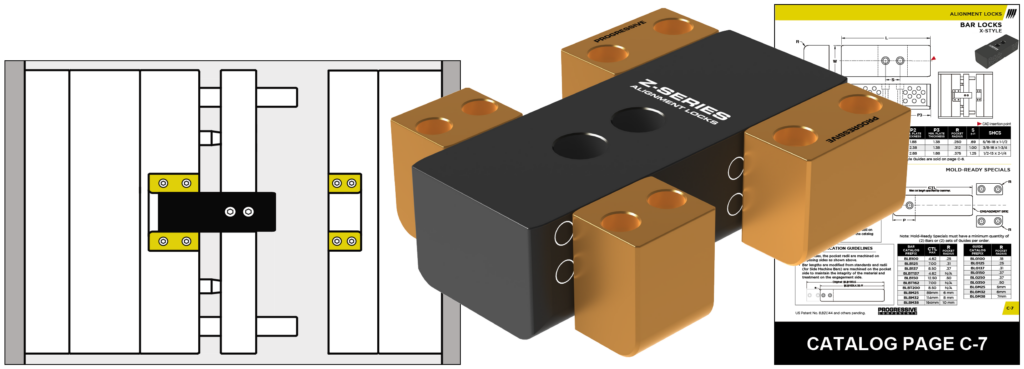

X-STYLE BAR LOCKS

For multi-parting line tools, Progressive has added an X-Style Bar Lock configuration.

X-Style Bars are available in three sizes to pair with corresponding Guides.

Click HERE for more information and online ordering.

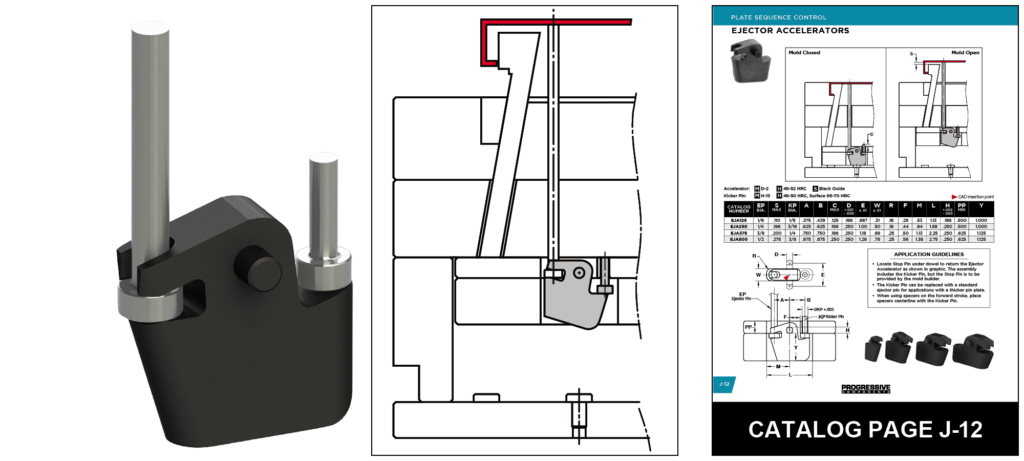

EJECTOR ACCELERATORS

Featuring a compact footprint and sized for inch ejector pins and ejector plates, Ejector Accelerators create a second-stage ejection without the need for a second set of ejector plates. They are designed to actuate an ejector pin forward when additional pin travel is required to release the molded part from lifters, stripper plates, or deep core features, are available in four standard-inch sizes and include a kicker pin and dowel pin installed.

Click HERE for additional information and online ordering.

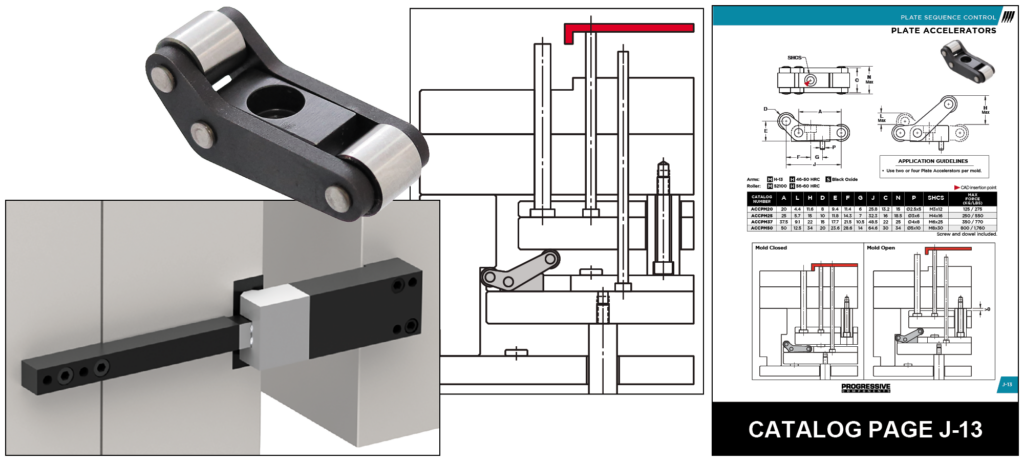

NEW PLATE SEQUENCING OPTIONS

To further build out Pro’s Plate Sequence Control program, new rocker-style Plate Accelerators have been added for double ejection applications, along with additional sizes of Latch Locks for large multi-parting line tools.

Click HERE for additional information and online ordering.

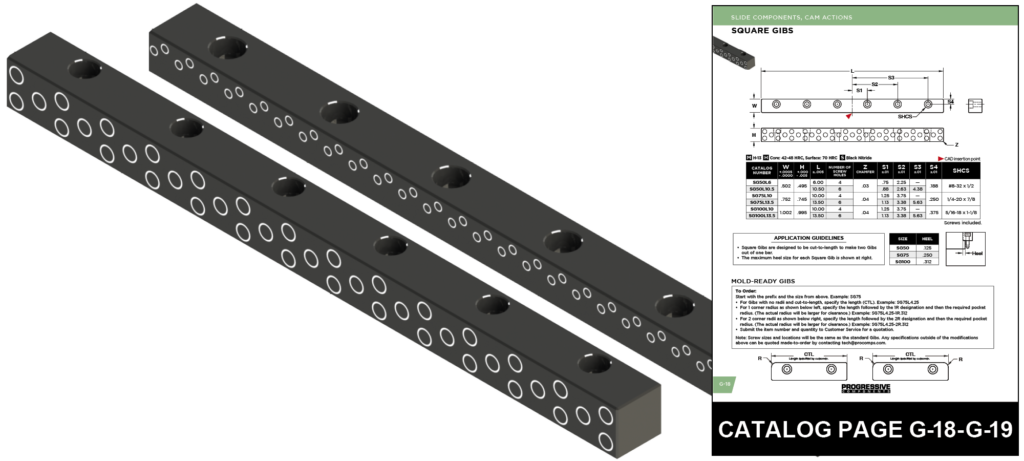

SQUARE GIBS AND CENTER GUIDES

To further build out Pro’s Plate Sequence Control program, new rocker-style Plate Accelerators have been added for double ejection applications, along with additional sizes of Latch Locks for large multi-parting line tools.

Click HERE for additional information and online ordering.

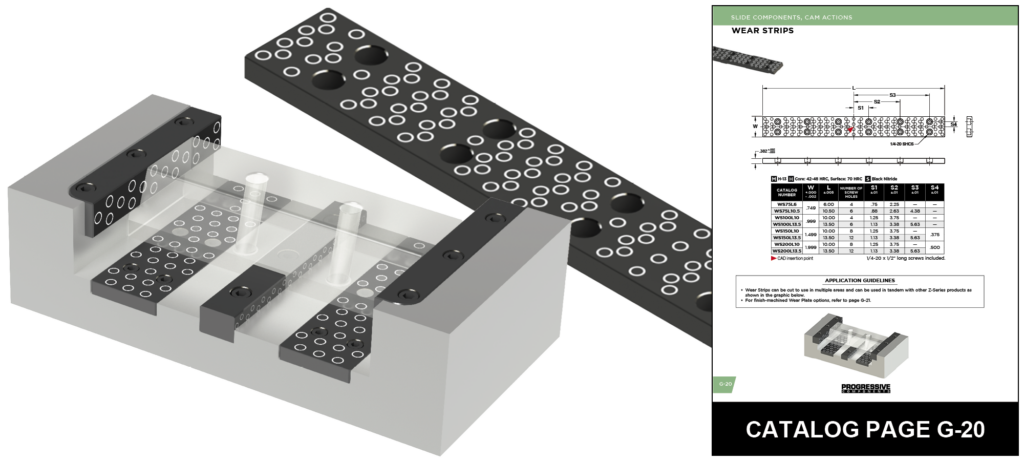

WEAR STRIPS

Wear Strips offer a time-saving approach for side action applications, needing only to be cut to the slide’s finished length required. Provided flat and including final fitting stock, Pro’s Wear Strips are easy to grind when compared to others’ bronze-plated steel or aluminum bronze wear plates and offer Pro’s Black Nitride for proven greaseless performance.

Click HERE for additional information and online ordering.

MOLD MONITORING ADVANCEMENTS

ProFile® Real-Time Monitoring and Asset Management now offers a more robust product with new features scalable to suit the needs of any organization. OEMs, Molders, and Mold Builders can now access one cloud-based program to monitor, maintain, manage, and track their tooling fleet and equipment, and a newly designed interface allows for various levels of visibility to help optimize production and maximize efficiencies.

Click HERE for more information.

THE MARCH TO NPE2024 HAS BEGUN!

As we introduce new components with the release of our v15 catalog, the Progressive team continues to execute new product development projects to further expand our offering later this year.

And, with NPE 2024 just under one year away, we are also preparing to unveil new exclusive components and innovative technology by day and then rock your world by night!

Click the play button (at right) to see a quick video of our booth draw experience and get excited for what awaits you in Orlando, FL. May 6th, 2024, is the date, and Booth 1543 will be THE place!

I-WARRIORS - HEROES FROM THE AMERICAN MOLD

The first iWarriors W

Progressive and our iWarriors volunteers are grateful to all the golfers and sponsors who made this event possible. We invite you to mark your calendars for the second annual event—February 9, 2024 (the Friday after MD&M/Plastec West 2024)—which looks to be even bigger and better!

For our Midwest and East Coast colleagues and friends, we are excited to announce that the annual Alliance Golf Outing will be held Friday, September 22nd, at the Countryside Golf Club, in Mundelein, IL, with a 12:00 PM shotgun start. The annual United Tool & Mold Golf Outing is scheduled for Friday, October 27th, with more details coming soon.

For additional information on the iWarriors program, to make a donation, become a sponsor, or purchase branded merchandise from the iWarriors Shop, please visit www.iwarriors.org.

For questions and more information: