cOUNTDOWN TO PROGRESS

cOUNTDOWN TO PROGRESS

Progressive’s 9th K Show is in the books and once again has exceeded our expectations. With the overwhelming response to our latest mold monitoring advancements, we look forward to bringing this next-level production asset visibility to the industry.

Progressive’s 9th K Show is in the books and once again has exceeded our expectations. With the overwhelming response to our latest mold monitoring advancements, we look forward to bringing this next-level production asset visibility to the industry.

Now is the time to review budgets and plan for the year ahead. Make 2023 your best ever with exclusives from Progressive, and mark your calendars for opportunities to connect with our team at upcoming events.

For information, registration links, and more, visit our website at procomps.com/industry-events.

Now is the time to review budgets and plan for the year ahead. Make 2023 your best ever with exclusives from Progressive, and mark your calendars for opportunities to connect with our team at upcoming events.

For information, registration links, and more, visit our website at procomps.com/industry-events.

VERSATILE ASSET TRACKING SYSTEM FOR MANUFACTURING

VERSATILE ASSET TRACKING SYSTEM FOR MANUFACTURING

Introducing the new ProFile® v4, the industry’s most comprehensive cloud-based asset management system for OEMs, Molders, and Mold Builders, which now includes added features designed specifically for different manufacturing roles and priorities:

OEMs—Monitor Global Assets

- Real-time visibility to performance and key metrics.

- Track Preventive Maintenance adherence, mold condition, data, and GPS location.

Molders—Monitor Production

- Track Downtime and Rejects to report OEE.

- Monitor all assets – molds, dies, machines, and equipment.

Mold Maintenance and Repair

- Access to a complete Work Order system.

- Track spare parts inventory and parts consumed

- Ability to generate true cost of maintenance reports.

Supply Chain Data Sharing

- Utilize APIs to connect ProFile with existing ERP/MES systems.

- Interface with CVe Monitors.

- Connect to report-generating platforms for custom reports.

ProFile’s intuitive user interface is suited for any role within an organization to deliver various levels of allowed visibility.

For a demo to evaluate your company’s needs and generate a budgetary quote, call 1-800-269-6653, send an email or visit our ProFile website at procomps.com/ProFile.

Introducing the new ProFile® v4, the industry’s most comprehensive cloud-based asset management system for OEMs, Molders, and Mold Builders, which now includes added features designed specifically for different manufacturing roles and priorities:

OEMs—Monitor Global Assets

- Real-time visibility to performance and key metrics.

- Track Preventive Maintenance adherence, mold condition, data, and GPS location.

Molders—Monitor Production

- Track Downtime and Rejects to report OEE.

- Monitor all assets – molds, dies, machines, and equipment.

Mold Maintenance and Repair

- Access to a complete Work Order system.

- Track spare parts inventory and parts consumed

- Ability to generate true cost of maintenance reports.

Supply Chain Data Sharing

- Utilize APIs to connect ProFile with existing ERP/MES systems.

- Interface with CVe Monitors.

- Connect to report-generating platforms for custom reports.

ProFile’s intuitive user interface is suited for any role within an organization to deliver various levels of allowed visibility.

For a demo to evaluate your company’s needs and generate a budgetary quote, call 1-800-269-6653, send an email or visit our ProFile website HERE.

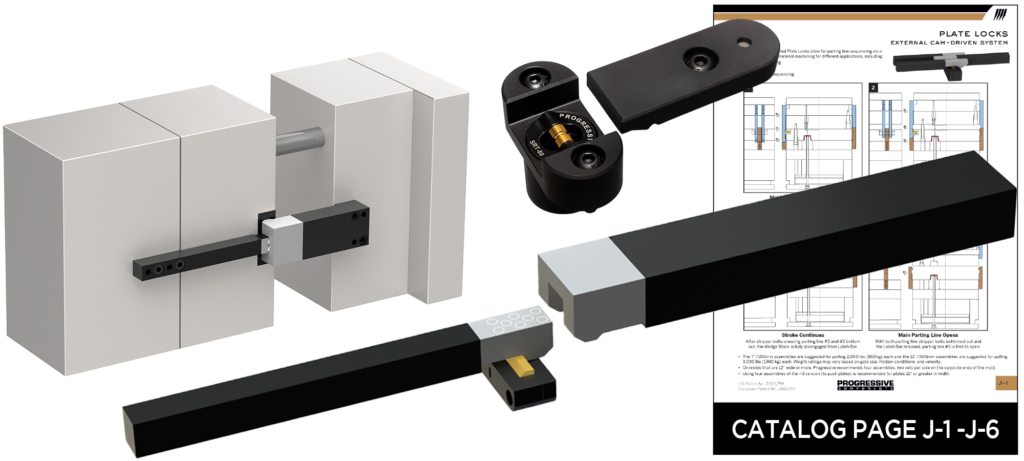

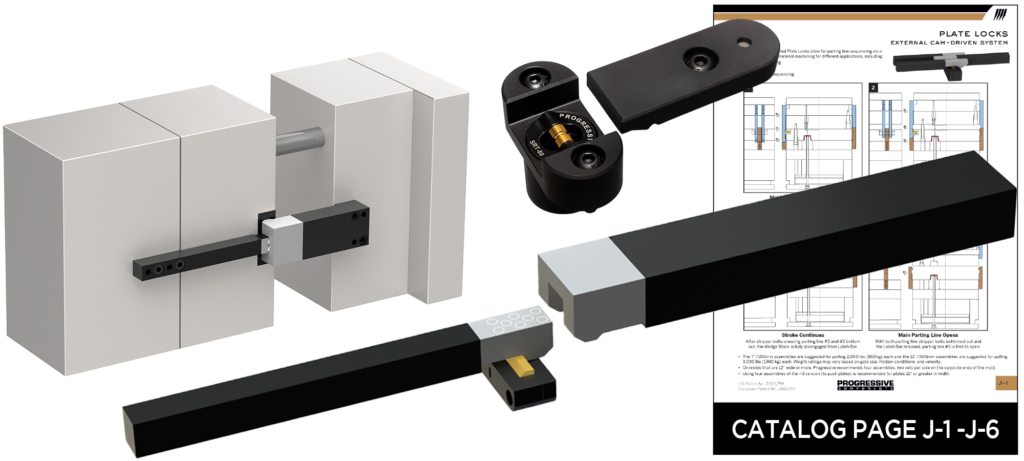

nEW PRODUCTS FOR PLATE SEQUENCING

nEW PRODUCTS FOR PLATE SEQUENCING

- Designed specifically for use with large molds and featuring a recommended pulling limit of 6,000 lbs (2,700 kg) each, Progressive’s new large Plate Locks offer longer 16” Standard Bars and Cam Bars machined from a single piece of steel eliminating the need for a Guide Block.

- Plate Retainers, a compact new method to hold parting lines

or retain plates for sequence functions incorporates the

SRT Slide Retainer for greaseless retention.

- Designed specifically for use with large molds and featuring a recommended pulling limit of 6,000 lbs (2,700 kg) each, Progressive’s new large Plate Locks offer longer 16” Standard Bars and Cam Bars machined from a single piece of steel eliminating the need for a Guide Block.

- Plate Retainers, a compact new method to hold parting lines

or retain plates for sequence functions incorporates the

SRT Slide Retainer for greaseless retention.

AS FEATURED IN MOLDMAKING TECHNOLOGY

AS FEATURED IN MMT

October was Manufacturing Month—a time to celebrate and highlight the manufacturing industry’s many contributions to the state and nation—and Christina Fuges, MoldMaking Technology’s Editorial Director shared an article on Progressive’s Tooling for Tomorrow program for its work in helping to develop the current and future moldmaking workforce.

To view the full article, scan the QR Code or visit short.moldmakingtechnology.com/Tooling4tmrw.

To learn more visit procomps.com/TFT, and to submit a request for donation, contact Sara Porter at Sara.Porter@procomps.com.

October was Manufacturing Month—a time to celebrate and highlight the manufacturing industry’s many contributions to the state and nation—and Christina Fuges, MoldMaking Technology’s Editorial Director shared an article on Progressive’s Tooling for Tomorrow program for its work in helping to develop the current and future moldmaking workforce.

Click HERE to view the full article, visit procomps.com/TFT to learn more about TFT, and to submit a request for donation, email Sara Porter HERE.

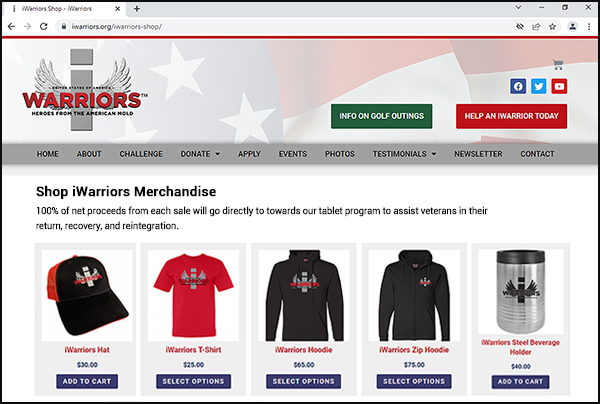

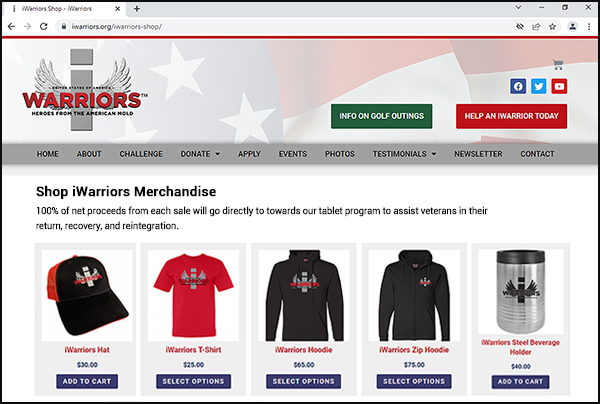

I-WARRIORS - HEROES FROM THE AMERICAN MOLD

I-WARRIORS - HEROES FROM THE AMERICAN MOLD

iWarriors was the beneficiary of two industry golf outings this fall.

On September 23rd, Alliance Specialties and Laser Sales hosted their Annual Charity Golf Outing raising a total of $33,681. Then, on October 21st, United Tool & Mold Inc. held their Golf Outing, which raised another $27,000.

Through the incredible efforts of our industry colleagues and friends, together we raised over $60,000 to continue our mission of providing iPads to our country’s wounded veterans.

iWarriors was the beneficiary of two industry golf outings this fall. On September 23rd, Alliance Specialties and Laser Sales hosted their Annual Charity Golf Outing raising a total of $33,681. Then, on October 21st, United Tool & Mold Inc. held their Golf Outing, which raised another $27,000.

Through the incredible efforts of our industry colleagues and friends, together we raised over $60,000 to continue our mission of providing iPads to our country’s wounded veterans.

For additional information on the iWarriors program, to make a donation, become a sponsor, or purchase branded merchandise from the iWarriors Shop, please visit www.iwarriors.org.

For additional information on the iWarriors program, to make a donation, become a sponsor, or purchase branded merchandise from the iWarriors Shop, please visit www.iwarriors.org.

For questions and more information:

For questions and more information: