Advancing Standards throughout the year

Throughout the plastics industry, businesses had concerns about their future as we entered March and April, and Progressive was no different. But with an innovative product line and a healthy, creative customer base, the year has been a solid one.

We’re grateful for that, as we have been able to execute new product development projects, further expand our greaseless and stainless offerings, and continue to advance our mold monitoring and mold maintenance innovations.

We are proud to announce our v13 catalog release, which includes over 2000 new items to address needs across the tooling and molding world. This issue of the Progress Report contains a glimpse of some new products, and on page 6, we share some useful website links. To request a copy of Pro’s new catalog please click HERE or call 1-800-269-6653.

Next, Progressive’s focus is towards more innovative introductions at NPE2021, where we hope to see you and your team online or in-person.

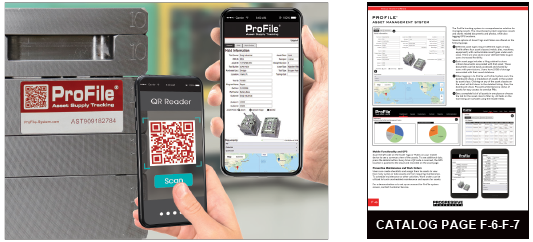

Profile asset management system

The ProFile® tracking and maintenance system simplifies the organization of molds, dies, machines, and equipment. The cloud-based system houses information and related documents or photos, while also logging GPS locations. Several Asset Tag and Plate layouts are available, and tags and plates with your company logo and information can be ordered.

Call 1-800-269-6653 to receive info on this affordable system developed for the mold building and molding industry.

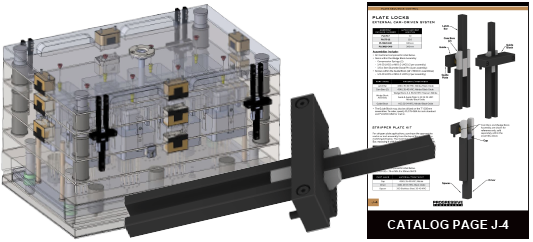

large plate locks added

Cam-Driven Plate Locks allow for parting line sequencing via a versatile design with minimal machining for 3-Plate, Dual Ejection, and Stripper Plate molds. For 3-plate tools that require robust features and precision timing, Progressive now offers new, longer length assembly options that come complete with a guide bar to aid in production.

rhinofeet: eliminate a shop hazard

Through an alliance with Rhino Visions, Progressive now offers the RhinoFoot product line to eliminate the hazards associated with placing molds and plates on wood blocks and pallets. RhinoFeet™ and RhinoToes™ offer a working load of 7,000 lbs and are each sold in packages of four.

nozzle tips, nozzle caddie, and wrench

Progressive now offers a new, patented Nozzle Tip featuring heat sinking fins to eliminate mold damaging stringing. To keep Nozzle Tips within reach, the new Nozzle Caddie magnetically mounts to the molding press. And, because removing and installing nozzle tips can be a real ‘knuckle buster,’ our new Offset Slugging Wrench is the preferred tool for mold setup personnel.

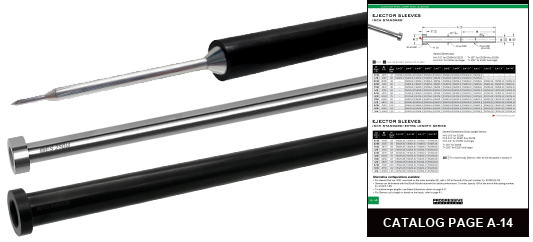

ejector sleeves: longer lengths, longer lasting

Progressive has added 300 new sizes to its range of H-13 Ejector Sleeves. Where U.S. standards end at 14” lengths, Progressive now offers off-the-shelf sizes in 15”, 16”, 17”, and 18”. Also added are new Black Nitride Sleeves, which feature a precision honed lubricious surface that does not require grease in cleanroom applications, and a high hardness (66-70 HRC) suited for the harsh conditions of die casting.

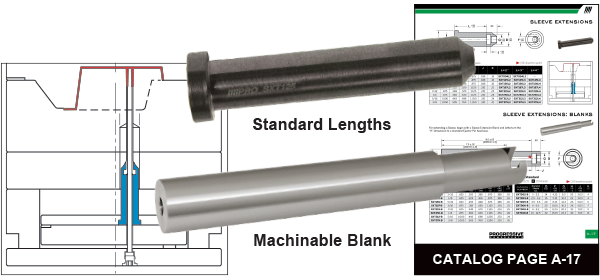

sleeve extensions: new sizes and options

New sizes of Sleeve Extensions are now available in 2” and 4” lengths. Also added is the new Sleeve Extension Blank (available in inch and metric options), allowing customers to extend their sleeves further.

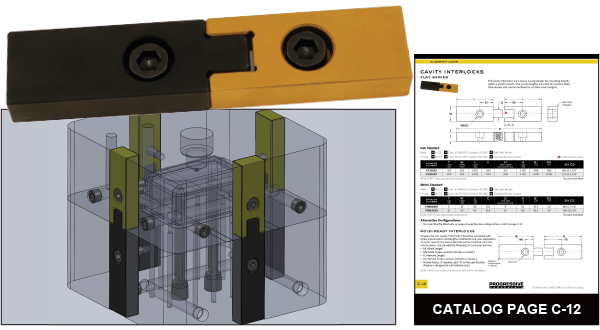

cavity interlocks: flat series

Progressive’s new Flat Cavity Interlocks are a space-saving design for mounting directly within a mold’s inserts. Overall lengths are sized for nominal plate thicknesses beginning at widths of only .625”, and lengths can be modified to suit the height of cavity and core inserts.

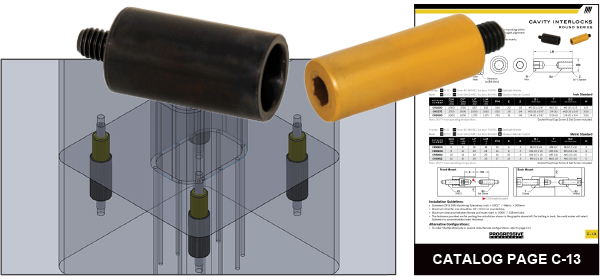

cavity interlocks: round series

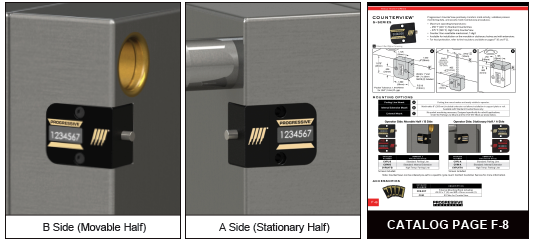

industry exclusive: counter for either mold half

The new industry exclusive S-Series CounterView can be viewed from the operator side when mounted on the stationary half / A side of the mold.

counterview: high temperature

The new High Temp CounterView offers the same functionality as Pro’s standard cycle counter with the added benefit of sustainability in higher temperature tools operating at a maximum of 375° F (190°C). Progressive’s CounterViews can be ordered pre-set to a specific cycle count for direct replacement.

insulator block: external mount

Designed to protect the CVe Monitor and CounterView when molding high-temperature resins, the exclusive External mount Insulator Block allows Progressive’s monitoring devices to perform at mold temps up to 360°F (180°C). Installation can occur on the cavity or core half of the tool. When using CVe Live, mounting is recommended on the stationary half for optimum cable routing.

insulator block: retrofit bracket

Insulator Blocks protect Progressive’s monitoring devices in high heat applications. The new Retrofit Bracket installs within an existing pocket without any modification to the mold’s cavity or core half, allowing the CVe Monitor or CounterView to perform at temps up to 410°F (210°C). The CVe Monitor and CounterView are actuated via a Striker, which is attached to the Insulator Bracket as a single unit. No preload adjustment is required.

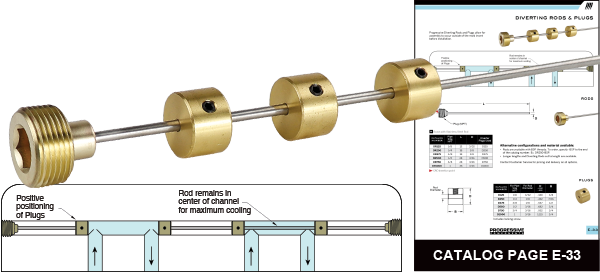

diverting rods and plugs

Diverting Rods and Plugs allow for assembly to occur outside of the mold insert before installation.

locking socket connectors

Locking Socket Connectors provide a positive locking connection to Extension or Connector Plugs. Connect and twist to lock the sleeve into place. To order, specify -L as the suffix to the standard items in the chart on page E-25. Examples: SC205-L (Standard Barbs), SC300B-L (Body), and SC326-PL-L (Push-Lok Barbs).

o-rings

Progressive’s addition of O-Rings provides designers with CAD geometry that includes the machine groove detail and makes replacement downstream easier for mold maintenance personnel. O-Rings are available in two material options: Buna-N for temps up to 225° F, and Viton for temps up to 400° F.

progressive thinking can be found at procomps.com

What’s New:

At Progressive, there’s always something new! Check out this page to read about recently added items and easily access catalog pages, animations, and more.

Product Animations:

If a picture is worth a thousand words, then an animation is worth a thousand pictures! This page features product-specific online demos to help mold buyers and mold designers visualize how mechanisms function. Not only are they informative, but they’re great “eye candy” for mold folks, as well as useful when training those who are new to the industry.

Mold Spec Guidelines, Mold Warranty, & More:

Progressive’s roots are in mold design, and throughout the years, we’ve developed free tools that have proven to be valuable to our customers and colleagues. At this page, one can view independent white papers on destructive testing and analysis of component wear and access cross-reference charts for mold finishes and international steel designations.

Are you developing a Mold Spec Book? Rather than begin with a blank doc, get a head start, and download our editable example to review and customize for your organization.

Are your customers asking for a Mold Warranty? View an article we wrote for MoldMaking Technology, then access our draft Mold Warranty, designed for users to review and customize to their individual needs.

www.procomps.com/resources

Running Greaseless?

More and more, molders are running greaseless in medical cleanroom environments and for cosmetic / appearance products. Unlike additive surface coating processes like DLC that can wear off, Black Nitride (BN) is diffused .003”-.005” into the component itself.

View a video excerpt that presents an exclusive Pin and Sleeve combination that delivers great performance for long-run cleanroom tooling to harsh die casting applications.

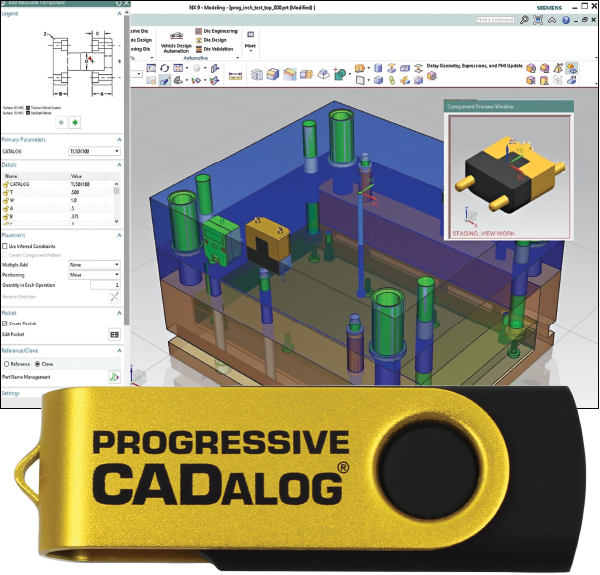

New v13 CADalog:

Progressive’s CADalog is a CAD Library for our entire range of products available as a file download or USB drive.

Created by mold designers for mold designers, geometry is available in native SolidWorks, NX (MoldWizard and ReUse), and VISI, as well as Neutral .step, .x_t, .sat, and .igs formats.

For questions and more information on any of the products listed above: