Whether you are building large single cavity molds for Automotive and Appliance applications or high cavitation molds for the Medical and Packaging markets, Progressive has exclusives for your tools:

New 5" RhinoFeet for Large Molds

Initially released in 2020, Progressive’s RhinoFeet™ have been established as a simple, safe, and efficient solution for elevating and storing heavy items within the shop. When used under molds, RhinoFeet eliminates the trip hazard of wood and skids strewn about the plant and improves 5S continuous improvement efforts.

NEW: Just added to the product line is a tall, 5” version that is designed to accommodate larger molds. Independently tested to hold 15,000 lbs. each and designated a safety factor of 3, a 60,000 lb. mold can be elevated with four 5” RhinoFeet.

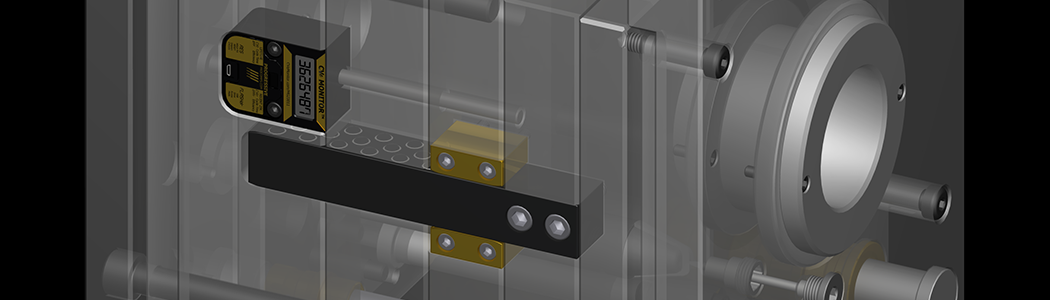

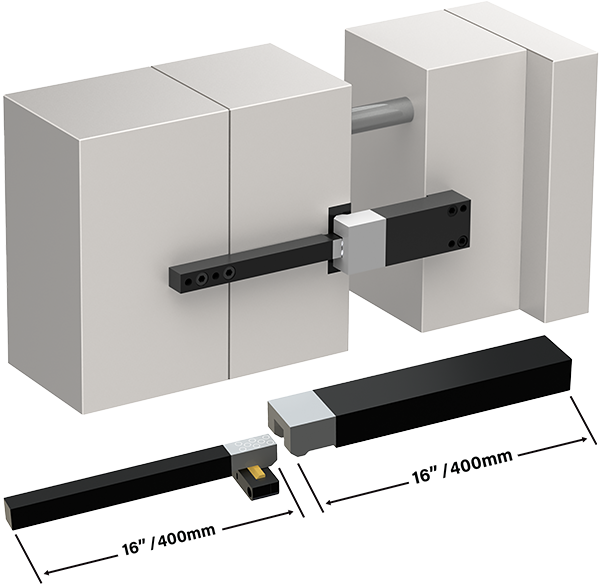

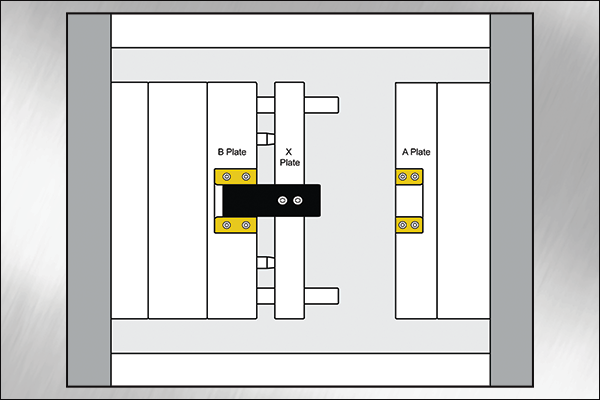

New Options for Plate Sequencing

Designed specifically for use with large molds, Progressive's new Cam Block Sequencing Plate Latch Locks (available in both inch and metric versions) offer a robust design with longer 16" (400mm) standard bars and feature a recommended pulling limit of 6,000 lbs. (2,700 kg) each. An additional feature of Pro's Large Plate Latch Lock is the Cam Bars are machined from a single piece of steel, eliminating the need for a Guide Block.

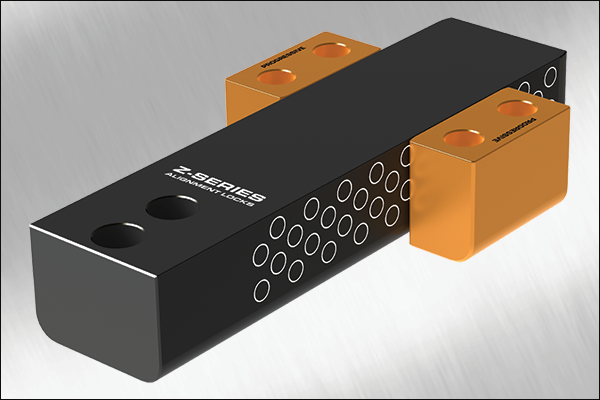

Largest Locks in the Industry

Progressive's Inserted Bar Locks are the largest, standard alignment lock in the industry. Designed for mold weights from 25,000 to 75,000 lbs, Inserted Bar Locks allow mold designers and molders to select off-the-shelf components for alignment of large molds. Inserted Bar Locks deliver the maximum amount of guidance and support for the minimum amount of machining required. Long-term, precision registration of plates, is achieved when utilizing Progressive's Z-Series proprietary treatment, radial ramp lead-in geometry, and particle rings on the plate surface.

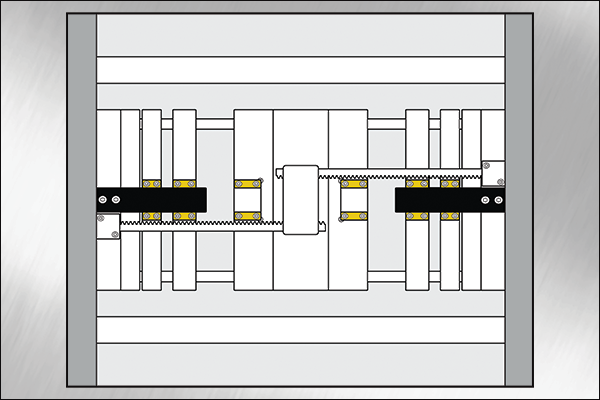

New Bar Locks Machined From Parting Line

Designed to be machined from the top at the parting line, new Top Machine Style Bar Locks simplify machining steps and increase pocket accuracy by allowing the alignment pockets to be machined on the same setup as cavity and core plate pockets. For multi-parting line tools, Progressive has also added an X-Style Bar Lock configuration. Both Top Machine and X-Style Bars are available in three sizes to pair with corresponding Guides.

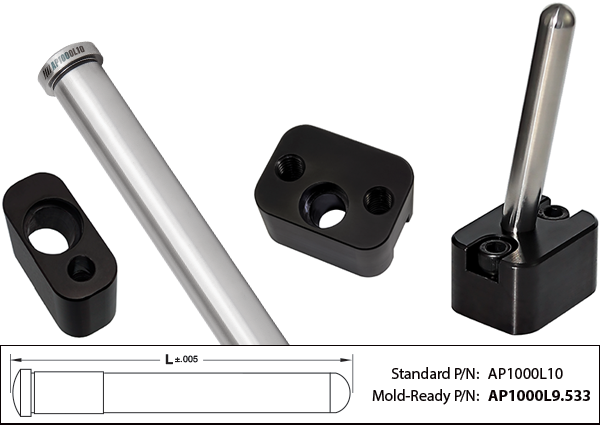

More Angle Pin Options

Progressive recently expanded its sizes of Angle Pins and Angle Pin Holders to accommodate larger tools. Angle Pins are available in 3/8”, 1/2”, 5/8”, 3/4”, and now 1” diameters and may be ordered Mold-Ready™, with a full radius machined to the length required.

NEW: To accommodate the larger 1” Angle Pins, Pro has added six new 1” Angle Pin Holders available with 10°, 15°, or 20° angled holes.

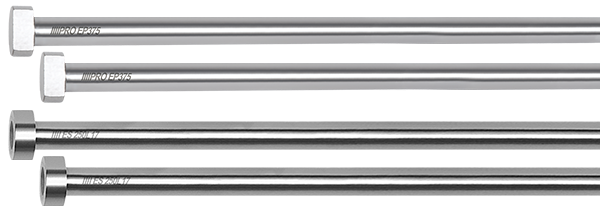

Longer Standards for Pins and Sleeves

Progressive’s through-hardened H-13 Ejector Pins are now available in common diameters in 50” lengths. Although these are large pins, Progressive’s tight tolerancing is still maintained, and as with all of our Pins and Sleeves, they can be supplied keyed by adding "-K" to the catalog number.

Also, only Progressive offers off-the-shelf Ejector Sleeves in 15”, 16”, 17”, and 18” lengths with Sleeve Extensions available to bring the maximum total length to 27”.

Love what you see and want to view more? Visit procomps.com/New for all recently released components and software solutions from Progressive.