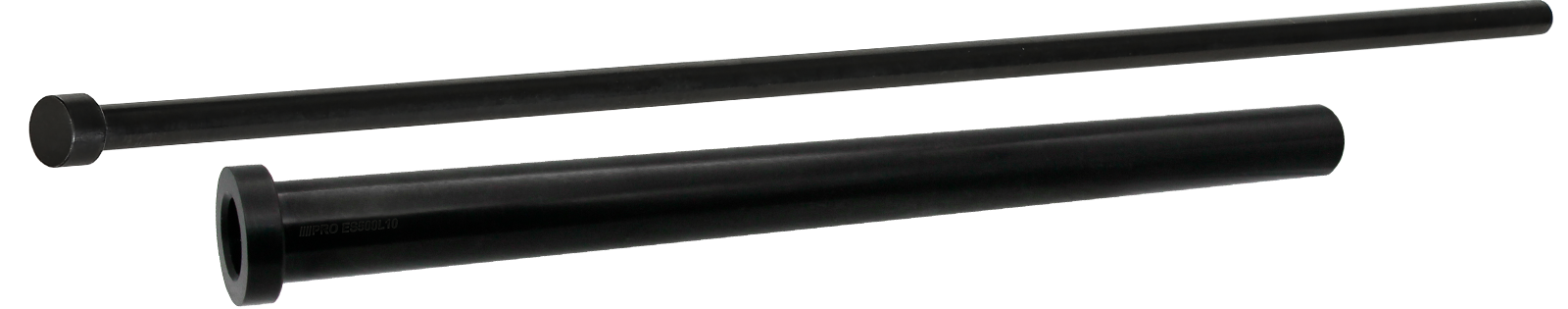

Progressive’s ejection components meet the sizing demands of moldmakers and the performance expectations of molders.

A moldmaker with a mic in hand can easily tell the difference between the precision of Progressive’s Ejector Pins and all others. That quality carries forward to better performance for molders.

Pro’s Ejector Pins are made from premium, through-hard H-13 with a surface resistant to wear and galling. Competitively priced, our pins also reduce unscheduled mold stoppages because of consistent, proven performance.

Want to check for yourself? Request a FREE Sample Pack today to verify these are the most accurate pins around.

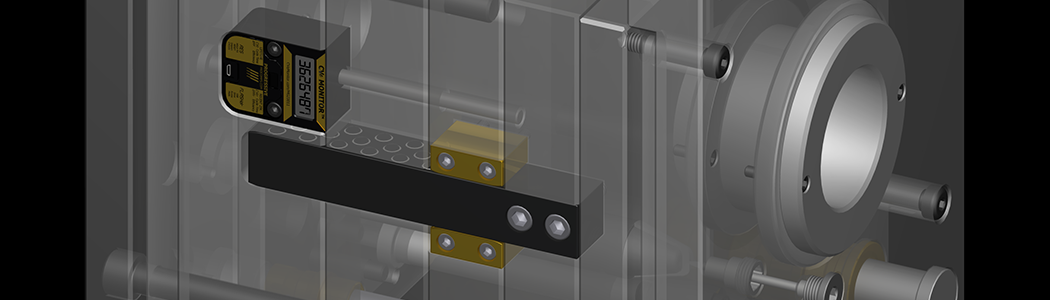

RUNNING GREASELESS

For further wear resistance in greaseless applications, turn to Progressive’s exclusive Black Nitride treatment, available on Ejector Pins and Ejector Sleeves. Unlike DLC and other coatings that can wear, this treatment penetrates and remains within the surface.

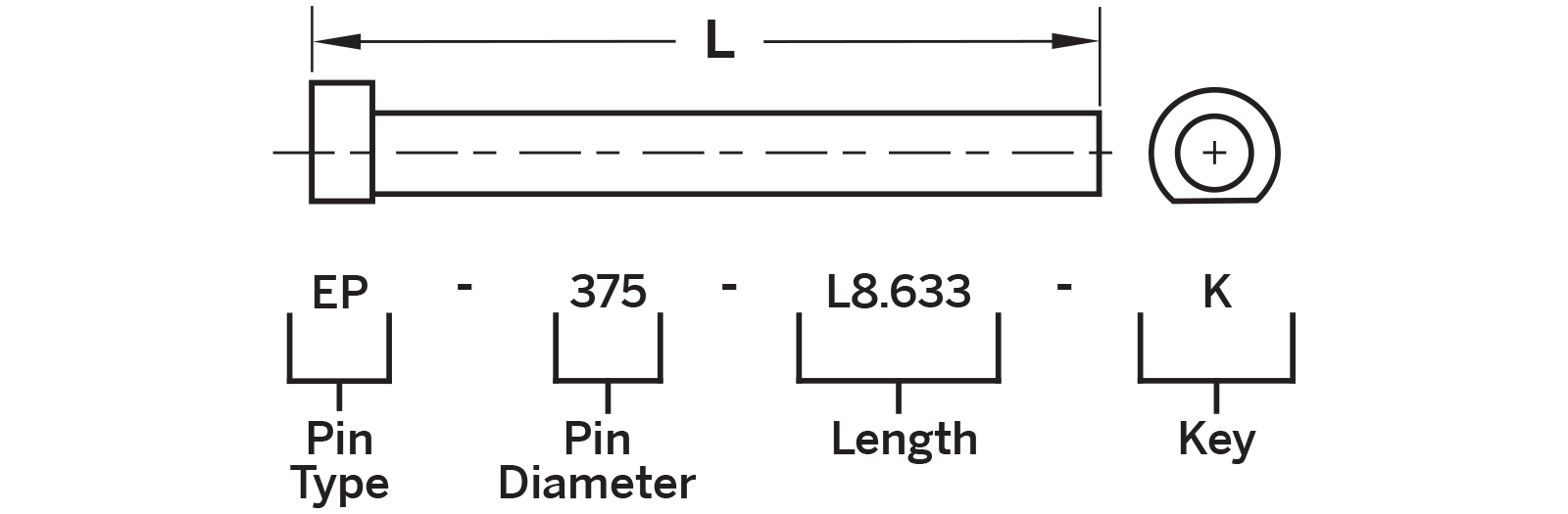

MOLD-READY™ EJECTOR PINS

Progressive can provide Mold-Ready™ Components to maximize your in-house labor. Pins and Sleeves can be keyed simply by adding “-K” after the standard catalog number (“EP375 L10-K”) or can be provided Cut-to-Length by modifying configurable part numbers (“EP375 L8.633”). Check out these ordering options and more HERE.

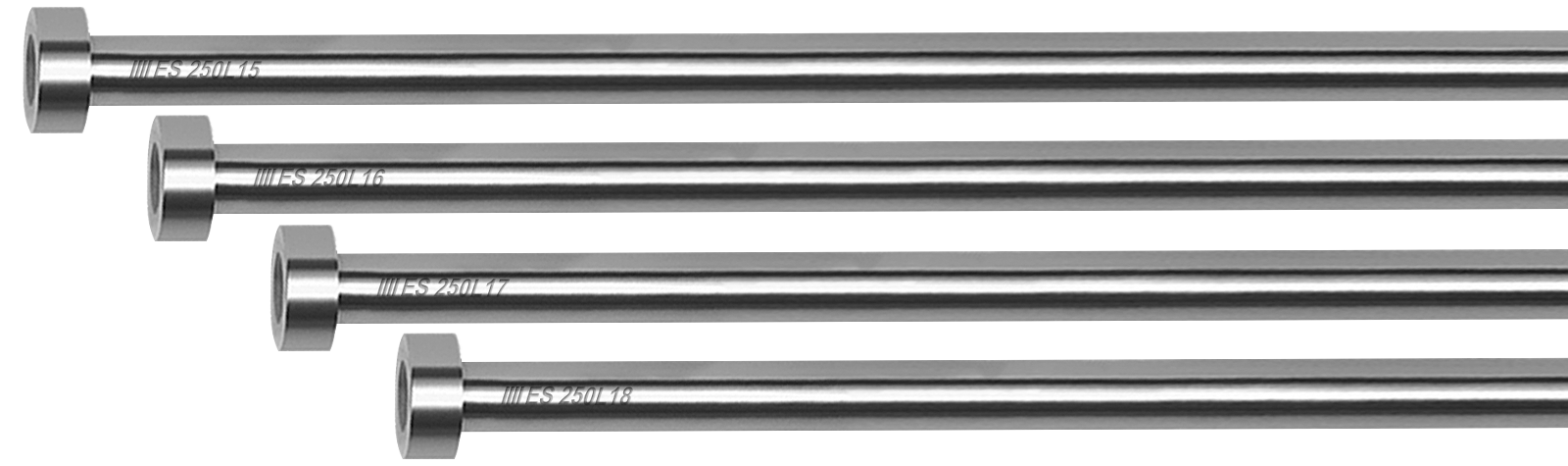

NEW, LONGER LENGTH EJECTOR SLEEVES

Progressive has added 300 new sizes to its range of H-13 Ejector Sleeves. Where U.S. standards end at 14” lengths, Progressive now offers off-the-shelf sizes in 15”, 16”, 17”, and 18”.

These are all examples of how Progressive works to provide the best standard components, with no made-in-China parts for your American-built molds.

To review any non-standard, custom components, please call 1-800-269-6653 or email tech@procomps.com and we will help provide options to match your specifications.