Industry exclusives from Progressive meet the demands for large injection molds and die cast dies.

Those that design, build, and run very large injection molds and die cast dies have unique demands that often have not been addressed with standard components. Progressive meets those demands and more by offering exclusive mold alignment locks designed specifically for the largest molds and molds with multiple parting lines.

LARGEST LOCKS IN THE INDUSTRY

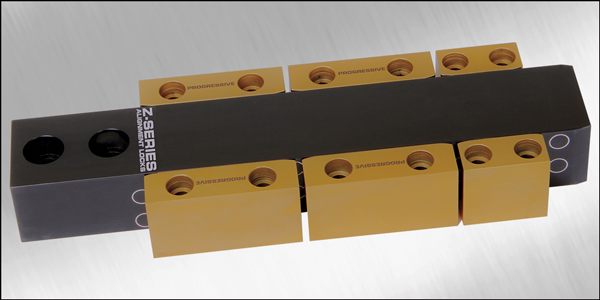

Progressive's Inserted Bar Locks are the largest, standard alignment lock in the industry. Designed for mold weights from 25,000 to 75,000 lbs, Inserted Bar Locks allow mold designers and molders to select off-the-shelf components for alignment of large molds. Inserted Bar Locks deliver the maximum amount of guidance and support for the minimum amount of machining required. Long-term, precision registration of plates, is achieved when utilizing Pro's Z-Series proprietary treatment, radial ramp lead-in geometry, and particle rings on the plate surface.

SIDE MACHINE STYLE BAR LOCKS

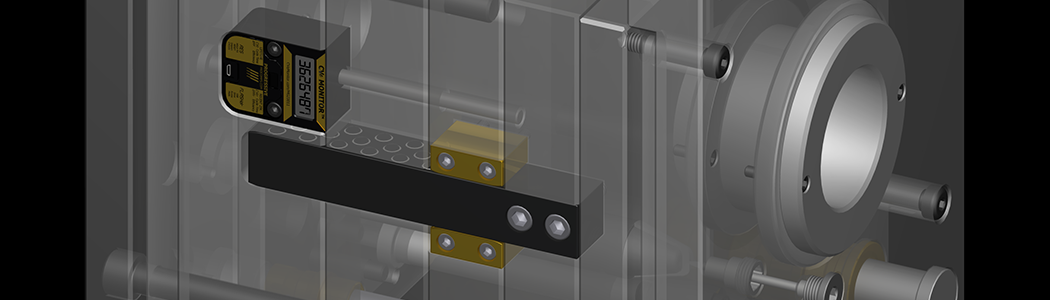

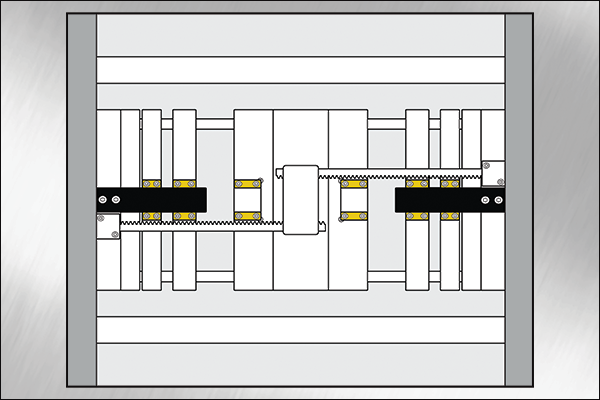

Progressive's Side Machine Style Bar Locks are an off-the-shelf solution for the alignment of large molds and multi-plate sequencing tools. Sized for standard mold bar plate thickness, bar lengths ranging from 4" to 16" long, and offer max supported weight loads of 10,000 lbs to 26,000 lbs.

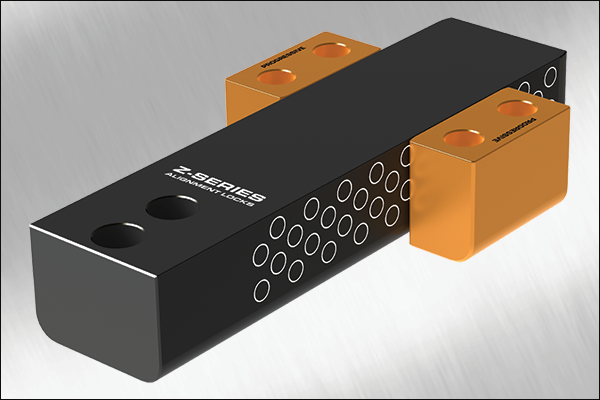

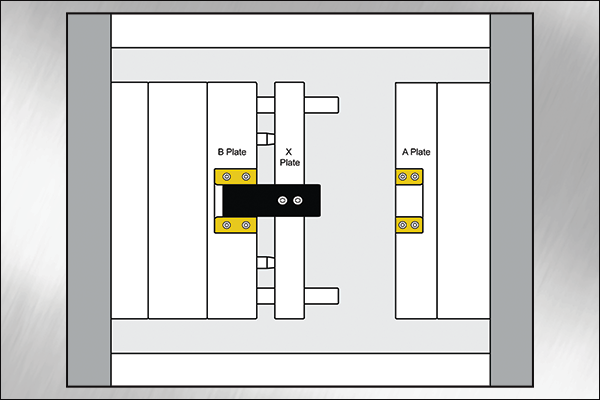

NEW BAR LOCKS MACHINED FROM PARTING LINE

Designed to be machined from the top at the parting line, new Top Machine Style Bar Locks simplify machining steps and increase pocket accuracy by allowing the alignment pockets to be machined on the same setup as cavity and core plate pockets. For multi-parting line tools, Progressive has also added an X-Style Bar Lock configuration. Both Top Machine and X-Style Bars are available in three sizes to pair with corresponding Guides.

We hope the information and links provided are a resource for you. Should you have any questions or need additional info, please call 1-800-269-6653 or click HERE to send us an email.