DID YOU KNOW?

Designing molds for the Medical sector requires unique approaches, and Progressive Components—headquartered in the northern Illinois Medical corridor—has exclusive items that cannot be found from anyone else.

Following is our Top 10 list of items that are designed to provide maximum performance and longevity of your critical medical tools:

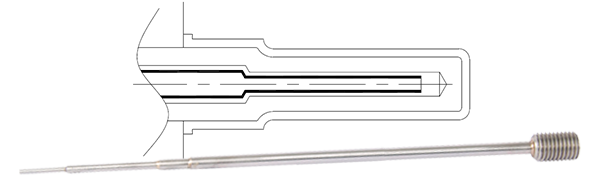

#10: Tapered Date Stamps

Our Tapered Series Daters feature a shut-off surface to prevent flash, even when running high MFI resins such as LSR, Nylon, and Medical-grade flex PVC. All Stainless Steel construction, this patented design has no height variation during rotation.

#9: Puller Pins and Bushings

Many tools either have 3-plate gating or are a “hot-to-cold” drop hybrid. For this, Progressive offers Puller Pins™ available off-the-shelf at nominal lengths to match standard plate thicknesses. Unlike how pins are typically finished in-house, Puller Pins are ion nitrided after the undercut geometry is finished and polished, resulting in a wear-resistant, ‘sealed’ surface. Then, rather than having pins riding against non-hardened mold plates, hardened Stainless Steel Puller Pin Bushings prevent wear and the resulting particulate.

#8: Stainless Steel Support Pillars

Every medical mold has them, but only Progressive has off-the-shelf 410SS Support Pillars, which are two and a half times harder than others’ 200 Brinell 1040 material.

#7: Medical Mold Base Components

Greaseless for medical (and durable enough for die casters), Progressive offers off-the-shelf Black Nitride Leader Pins and Bushings. Also, corrosion-resistant black oxide treated Locating Rings, Guided Support Pillars for small molds where space is tight, and PKO Extensions now available in longer standard lengths for insulator sheets on bottom clamp plates.

#6: Through-Hardened Ejection Components

Black Nitride Ejector Pins are available in-stock, as well as lubricious thin chromium-plated UltraPins. Core Pins and Sleeves can quickly be treated as needed, and cut-to-length for $1.00 and keyed for $0.75 per pin.

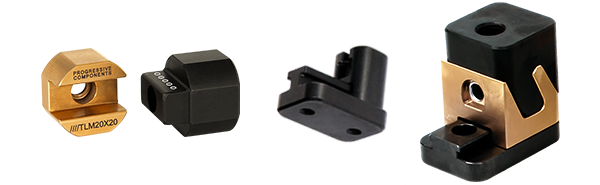

#5: Smooth Running Slide Retention

Instead of constant greasing required to prevent metal-to-metal wear under slides, SRT Slide Retainers with hardened 80 HRC TiN coated roller can run clean and dry, and now easier to install within the new hardened D-2 SRT Bushing.

#4: Exclusive "Black and Gold" Mechanisms

The combination of Titanium Nitride (TiN) and Black Nitride (SBN) has been independently tested and proven to outperform not only look-alike imitations but also DLC vs. DLC. The same technology proven for withstanding the “bump” of aligning mold halves due to platen sag has been applied in standard CamActions, as well the lubrication-free pairing up of UniLifter U-Couplings and T-Gibs.

#3: Options for Rapid Tooling

Rapid Tooling Inserts are in stock and ready for hot projects. As an option, inserts can also be made in Stainless Steel, and our frames are only available in Stainless.

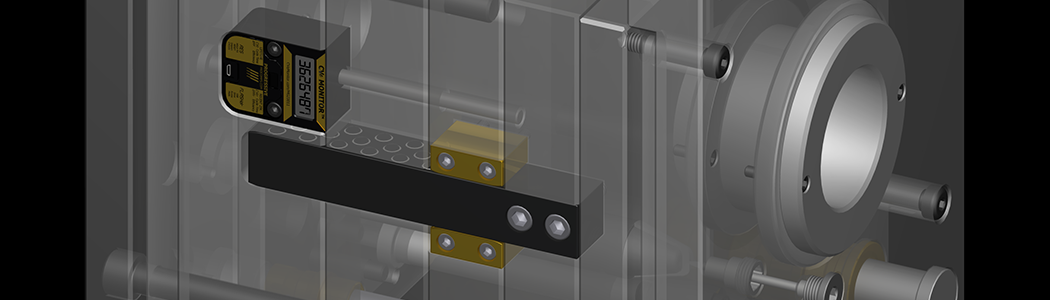

#2: Align Floating Plates

Medical tools often have more than one parting line, and only Progressive offers Bar Locks with multiple Guides. There are over twenty items in all, in both inch and metric sizes for standard plate thicknesses.

#1: Cooling is Key

Mold designers are always fighting to get water where needed, and Progressive has more exclusive and patented ways of delivering cooling than anyone. High Flow surgical Stainless Steel Tubes are unmatched in cooling round cores, and our Engineering team can do-the-math and help design stepped tubes that deliver an increase of flow of 20%-60%.

Also, we have Threadless Plugs for those who specify no tapping or introduction of stresses in their 420SS inserts, and Jumper Baffles and Reverse Flow Baffles provide an easy to drill, easy to maintain waterline. Last, at the design stage, think safety downstream and include Keyed Connectors and keyed sockets to prevent setup personnel incorrectly attaching cooling lines and hot oil circuits, and call out locking socket connectors for safety to be assured.

Every mold is different, and we hope that out of this Top 10, there will be at least a few new advantages for your company.

Have an immediate need or question? We're here to help. Please give us a call at 1-800-269-6653 or send a note to tech@procomps.com for a discussion or to setup a webinar for you and your colleagues.

Thanks,

The Progressive Engineering Team