DID YOU KNOW?

Progressive's Black Nitride products are proven to perform in medical cleanroom molding environments, cosmetic / appearance product production, harsh conditions such as die casting, and more.

"Progressive's Black Nitride Core Pins outlast all others 5 to 1. We trust these pins to perform in the harshest conditions."

Dan Sheridan, Twin City Die Castings

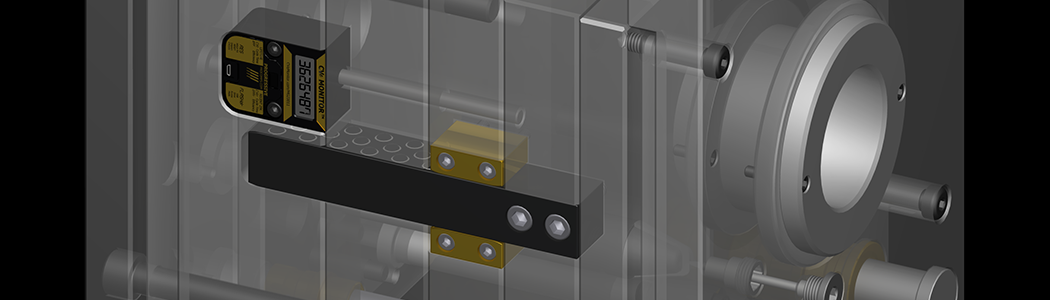

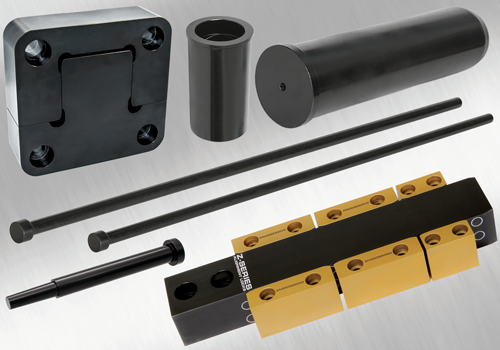

Progressive has used Black Nitride in our Locks and Lifters for years, and have now applied this treatment to Pins, Sleeves, Leader Pins, Bushings, and Wear Plates.

Benefits include:

Black Nitride (BN) is diffused .003"-.005" into the component. It is not an additive process that can wear off and end up in your parts like DLC and other surface coatings.

This treatment is especially advantageous with Ejector Sleeves, where the center Core Pin (our Through-Hard Ejector Pin) also is Black Nitrided. As an option, the Core Pin can be supplied with the black surface removed by diamond polishing.

Black Nitride Ejector Sleeves have a precision-honed, lubricious surface that does not require grease in cleanroom applications, and a high hardness (66-70 HRC) that is suited for harsh conditions such as with die casting.

If our Black Nitride products address any demands that you are facing give us a call at 1-800-269-6653 or click HERE to send an email. A PRO technical rep will be in touch to discuss your applications, and we can send samples your way so that you and your team can see the parts in-person.