PROGRESSIVE COMPONENTS HAS ADDED NEW PRODUCTS FOR:

- THREE-PLATE MOLDS

- STRIPPER PLATE MOLDS

- DUAL EJECTION APPLICATIONS.

Molds aren’t getting any simpler—just the opposite. To continue to be a resource for you to reach for, Progressive’s Engineering Team wanted to be sure we’re keeping you up-to-date with additions throughout our product line of innovations for complex, multi-parting line tools.

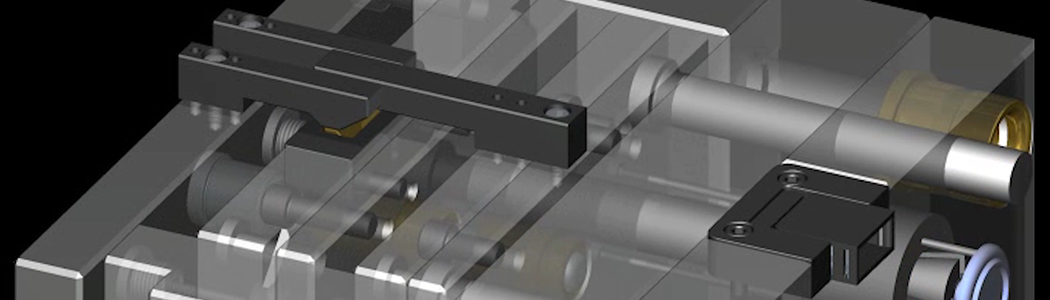

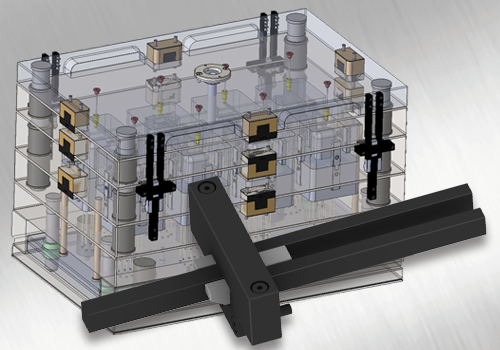

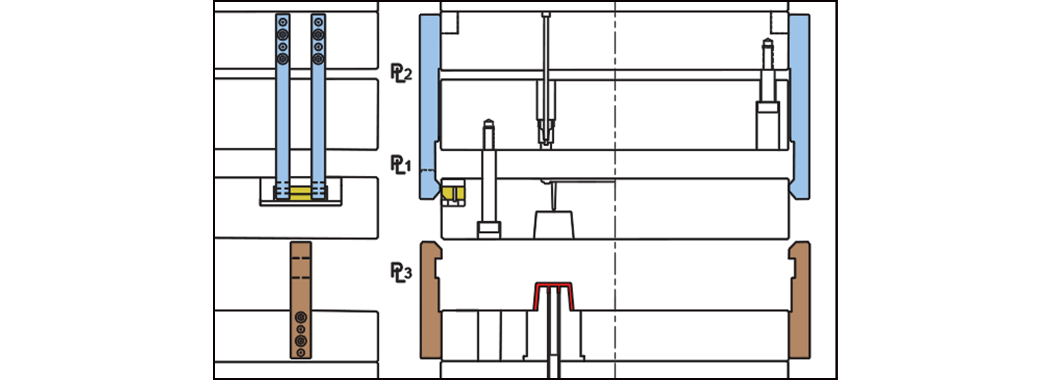

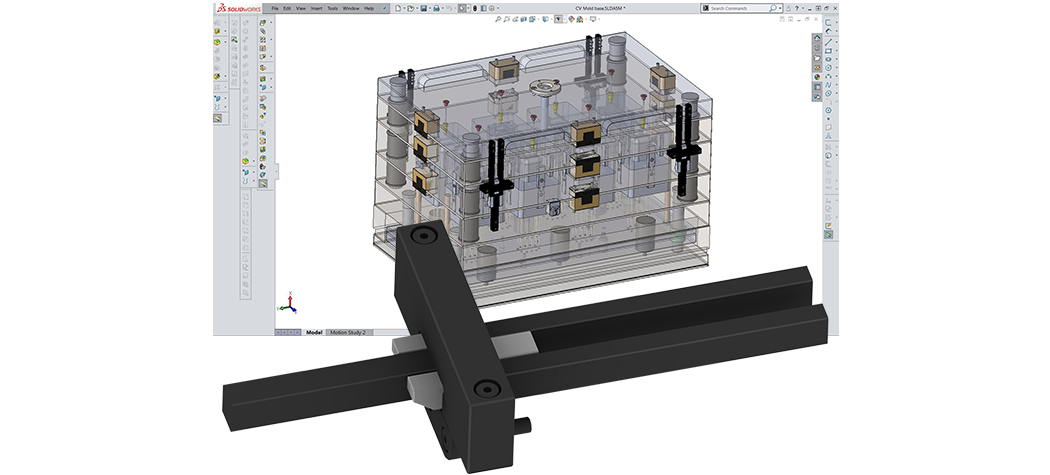

External Cam-Driven Plate Locks are a proven, reliable method for three-plate molds, stripper plate molds, and dual ejection applications. View our product animation HERE. Also, we've expanded this product line to now include a longer reach Latch Bar and a Guide to ensure that no deflection occurs. Catalog pages for this item are available HERE.

Progressive carries several products for multi-plate applications:

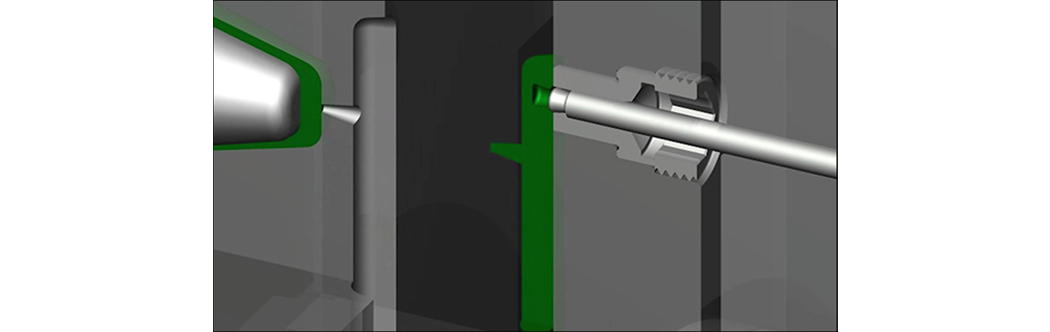

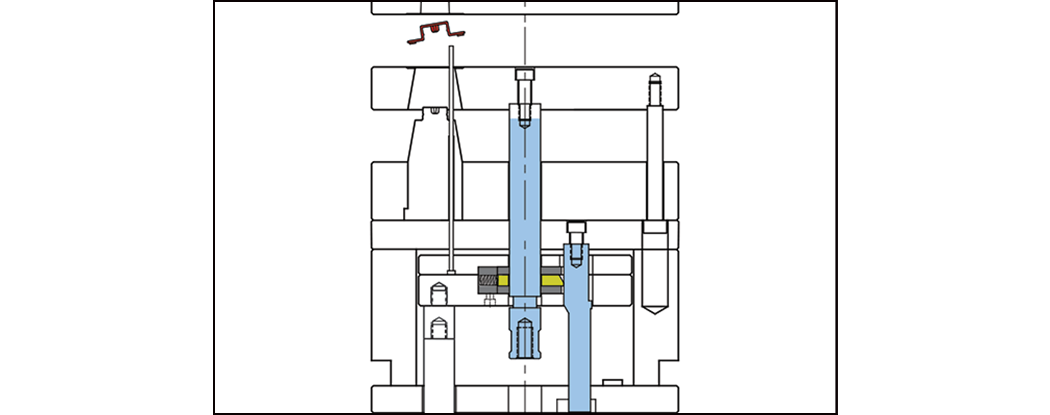

Internal Ejection: This mechanism provides an additional final part eject to occur in stripper plate molds, without the cost and maintenance of dual ejector plates. Our catalog page can be found HERE, and our product animation HERE.

Friction Pullers: Progressive advanced a previous standard, and this patented component’s self-adjusting feature prevents scoring when plates are sagging and are vented to eliminate additional machining in blind holes. Click HERE for catalog page and HERE for animation.

Roller Pullers: This friction-free approach requires a minimum amount of machining, and timing and installation is straightforward. Access the catalog page HERE and view the animation HERE

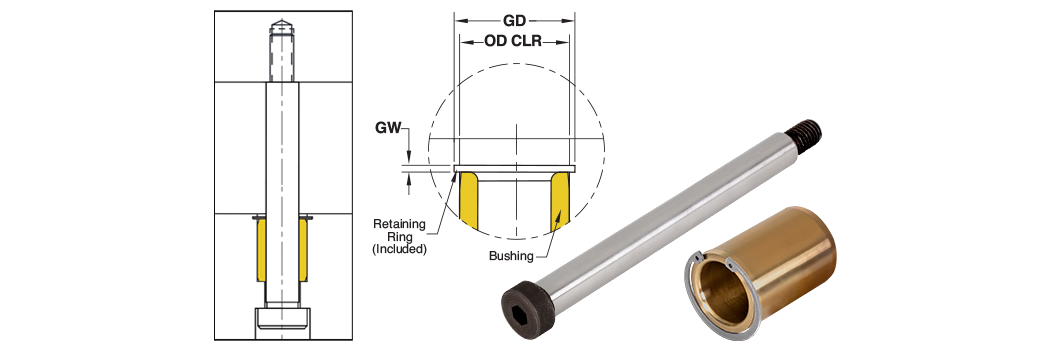

Stripper Bolts and Bushings: Others’ often require in-house machining for mold quality accuracy, but Progressive’s Stripper Bolts exceed industry standards with tighter length tolerance for uniform plate-stop positioning. Also, diameters are precise, to match with our Stripper Bolt Bushings.

Puller Pins and Bushings: While on the topic of multi-plate molds, Puller Pins and Bushings are a convenient way to eliminate wear, galling, and the resulting particulate of running pins against-hardened stainless steel mold plates. Unlike how pins are typically finished in-house, Puller Pins are heat-treated after the undercut geometry is finished and polished, resulting in a ‘sealed’ surface.

Aligning multiple plates just got easier:

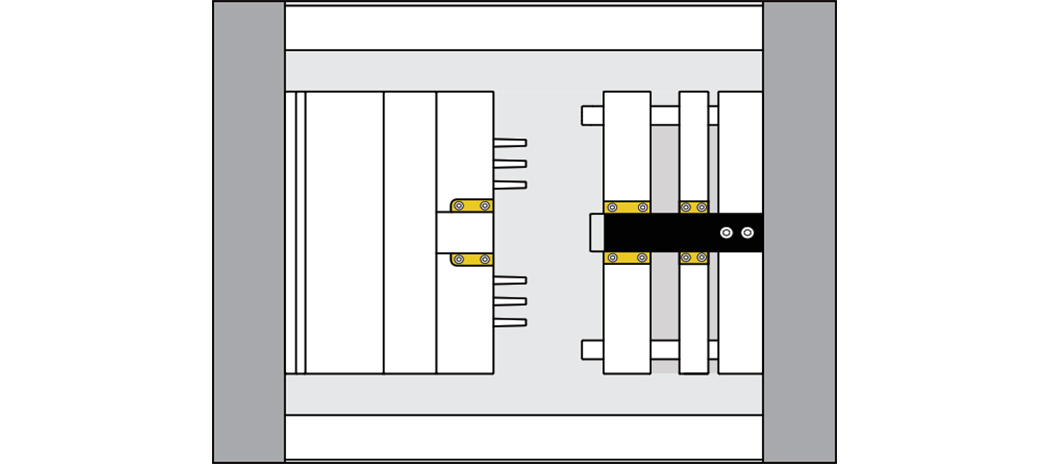

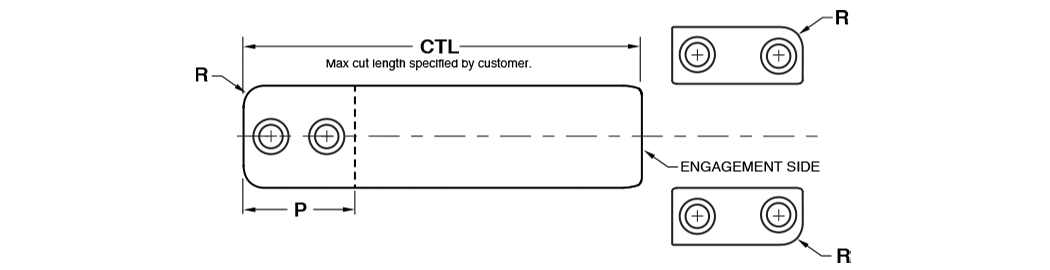

Z-Series Bar Locks: Progressive’s Bar Locks now have new sizes added, for both larger and smaller molds. And because there’s an infinite amount of plate stack-ups that would fall “in-between” standard sizes, we have also added configurable part numbers to our Mold-Ready offering.

For example, rather than ordering a “BLB100L-6” when a slightly shorter length is required, one can order a “BLB100L4.56” as a special, and if radii are required, add “-R” to the catalog number. Then, with quick delivery and economical pricing, it arrives at your door finish machined, ready for assembly. Guides also can be provided with radii when needed, simply by adding “-R” to the catalog number.

Progressive’s roots are in the packaging and medical mold market. Therefore we carry more exclusives to help efficiently design, build, and maintain multi-parting line tools that are common for these segments. If you have any questions regarding these or any of our items email us at tech@procomps.com, or call 1-800-269-6653. Our Engineering Team is here to assist!