Progressive Components recently added new products to support the unique needs of medical tools for clean room molding.

New product advantages include:

- Tapered Series Date Plugs, made from Stainless Steel, feature a tapered seal between the Date Plug and the Date Ring. Low viscosity resins commonly used in medical applications easily flash, and the tapered seal prevents that, eliminating potential non-conformances with the molded part.

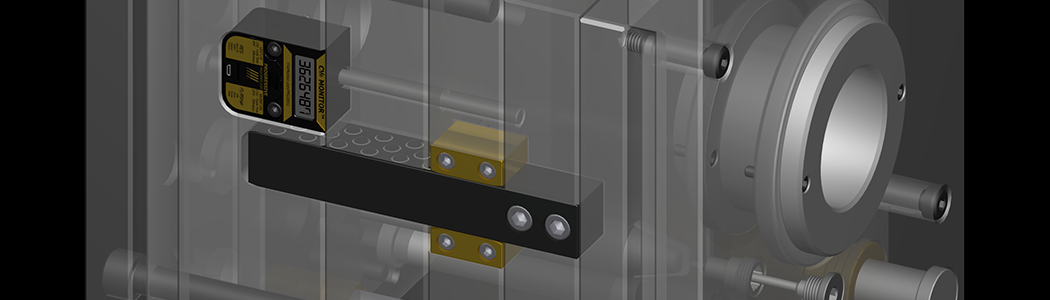

- Stainless Steel Support Pillars eliminate the allocation of labor and cost for medical mold builders to make custom pillars in-house.

These items join over a dozen products that Progressive has introduced with features that offer advantages within cleanroom environments.

“Our roots are in the medical mold market, being located in one of the world’s largest medical molding corridors,” states Glenn Starkey, President of Progressive Components. “Early on, we recognized that a high-demand, high-cost mold for medical applications should not have rusty mold base components, nor should the shop that built it make mold base components such as Locating Rings and Press Knockout Extensions. Whenever practical, we’ve made components from Stainless Steel or black oxided items for corrosion resistance, and now Support Pillars joins these items. And for the critical cavity/core area, the Tapered Series Date Plugs join exclusives such as friction-free Slide Retainers, Needle Bearing Locks and UltraPins treated for lubricity.”

For additional information or questions, please contact our Customer Service team at CustomerService@procomps.com.