Got Big Molds?

Progressive has added new, industry exclusives to address the unique demands of those that design, build, and run large injection molds.

Those that design, build, and run very large injection molds have unique demands that often have not been addressed with standard components. Progressive has added new industry exclusives to address these needs.

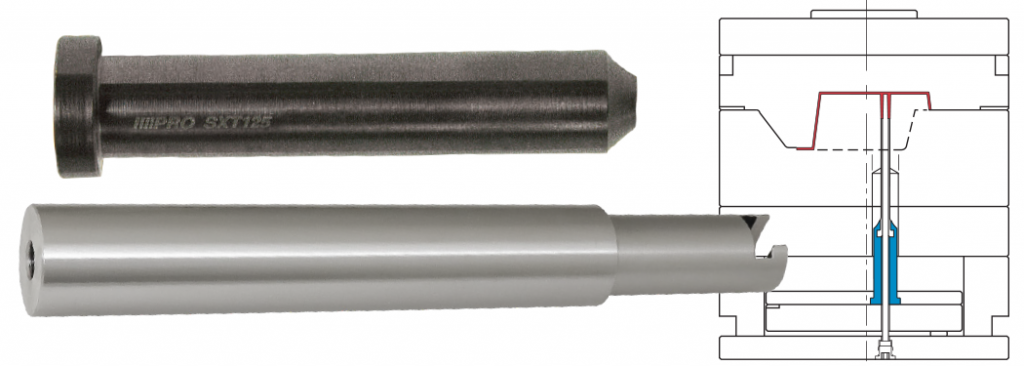

Longer Standard Ejector Sleeves

Progressive has added 300 sizes to its range of Ejector Sleeves. Where U.S. standards end at 14”, Pro now offers new, off-the-shelf sizes in 15”, 16”, 17”, and 18” lengths.

Longer Sleeve Extensions

The first to offer Sleeve Extensions as a standard, Pro has now expanded the line to include new sizes in 2" and 4" lengths and new machinable blanks that come complete with the detail work provided. By simply turning down the finished length and body, users can achieve an additional 9" extension. When combined with new, longer sleeves, lengths up to 27" are now possible with standard components.

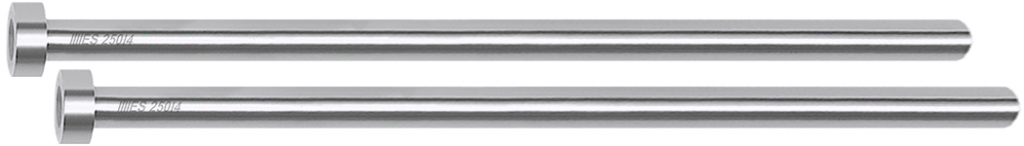

Longer Through-Hardened Ejector Pins

Progressive’s through-hardened H-13 Ejector Pins are now available in common diameters in 50” lengths. Although these are large pins, Progressive’s tight tolerancing is still maintained, and as with all of our Pins and Sleeves, they can be supplied keyed by adding "-K" to the catalog number.

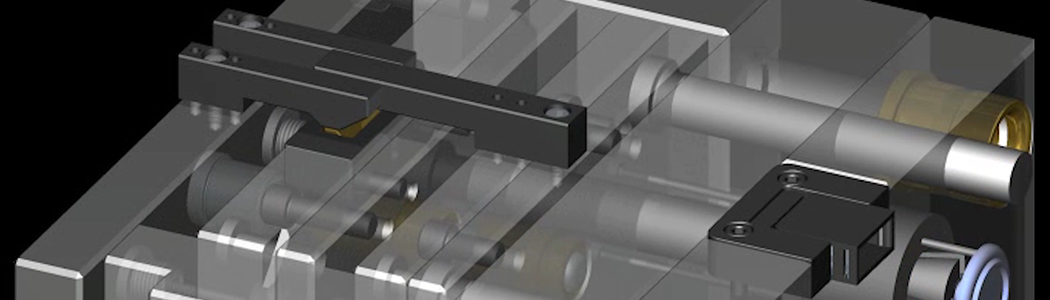

Largest Locks in the Industry

Mold designers now have more off-the-shelf options for the precision alignment of large molds with Pro's Bar Lock (largest size 1.50” x 3.00” x 16”, supports 25,000 lbs), the Inserted Bar Lock (largest size 3.50” x 6.00” x 13”, supports 75,000 lbs), and the BN Series Die Cast Side Lock (sized at 2" x 6.5" x 6.125" to support up to 25,000 lbs).

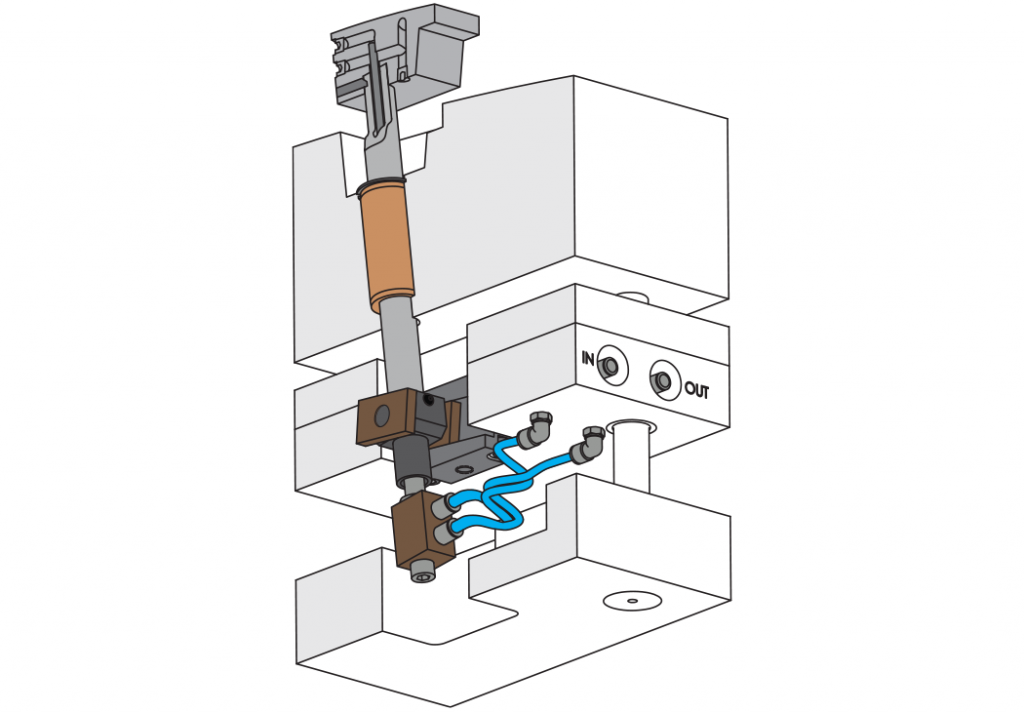

Pulling Undercuts in Large Molds

Progressive’s popular UniLifter features a series with 1.00” Diameter Rods, and our recently introduced ModuLifter features rod diameters as large as 1.250” and 1.500” in 18” lengths. Because large lifters often require cooling, standard components are provided.

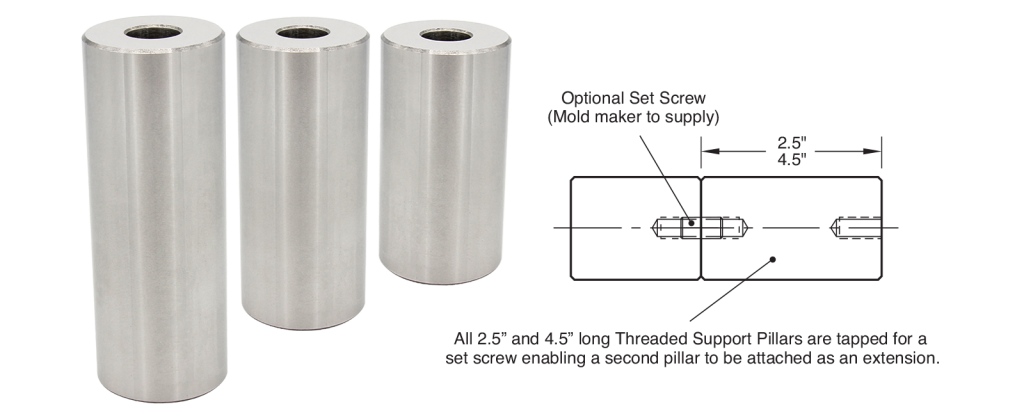

Exclusive, Large Support Pillars

Progressive carries the largest Support Pillars in the industry. Where others’ stop, Pro’s lengths continue on to 7”, 8”, and 9” long pillars. Also, only Progressive taps both ends of our 2.5” and 4.5” length pillars, allowing a second pillar to be attached.

Safe Placement of Big Molds

RhinoFeet™ eliminate the hazards associated with placing large molds and plates on wood blocks and pallets, and RhinoToes™ safely hold plates in position during assembly. Safer, cleaner, and improves 5S standards within the shop.

Click HERE for more information on RhinoFeet.

In addition, Progressive offers Date Stamps for structural foam and SMC molds, unique cooling components that allow unmatched routing of complex circuits, and large modular side actions. These are all included in a new catalog that you can request HERE, along with our CADalog™ available as downloadable files or provided on a USB drive, with geometry in native SolidWorks, NX (MoldWizard and ReUse), VISI, and Neutral .step, .x_t, .sat, and .igs formats.

We hope the links above provide advantages for your company. Please give us a call at 847-487-1000 / 800-269-6653 or email insidesales@procomps.com if you would like additional information or to discuss how these products can work for your applications.