Only Progressive offers the following collection of components for high-temperature injection molds.

A growing number of production tools are molding engineered thermoplastics such as Polycarbonate, PPS, PEEK, and LSR, which require higher than average mold temperatures or plasticize at temps from 300° F and above.

Progressive recognizes this and has formed a product line to specifically address the unique demands of high-temperature tooling within the design, around the mold, and throughout the plant.

WITHIN THE PLANT

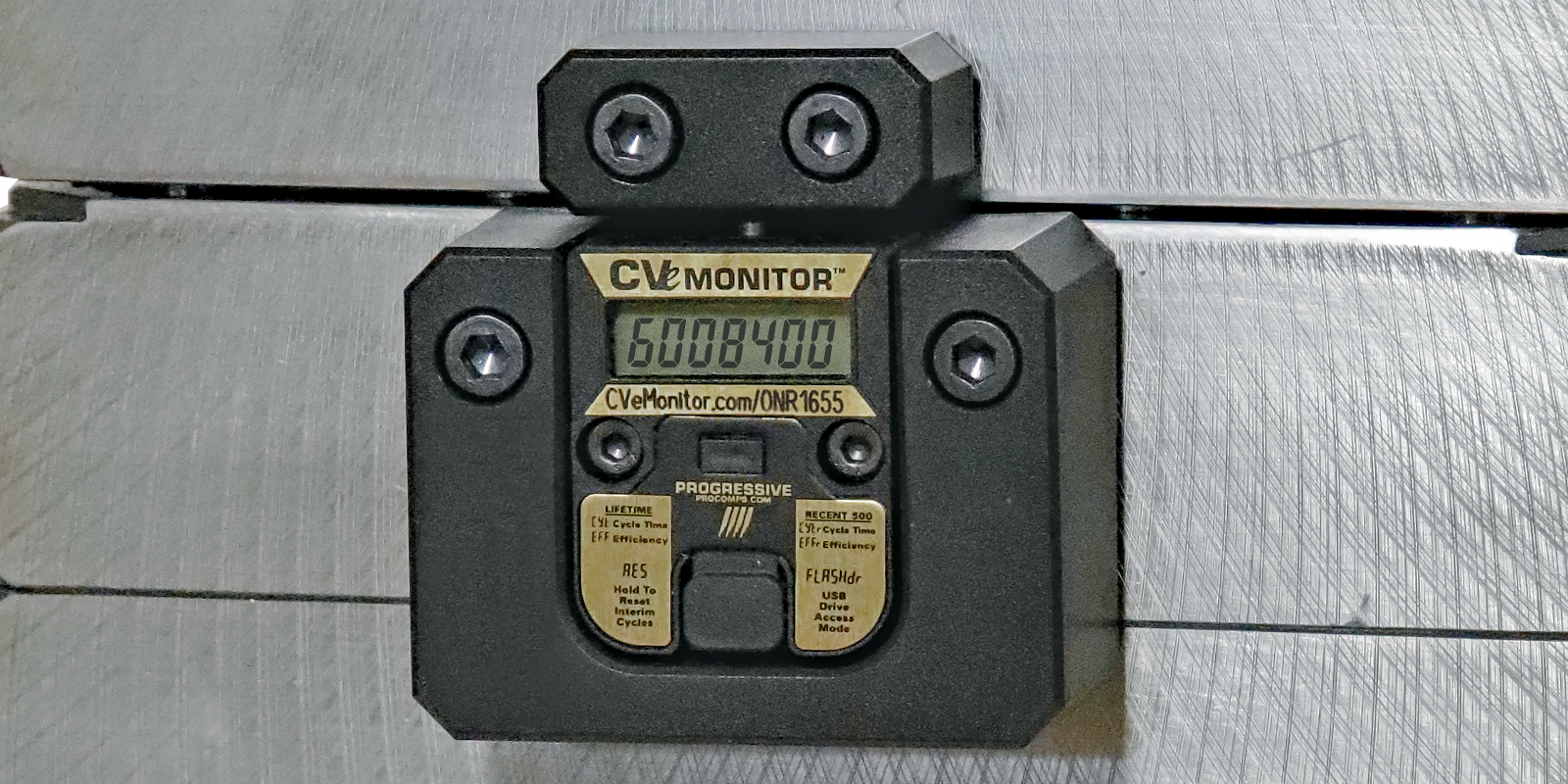

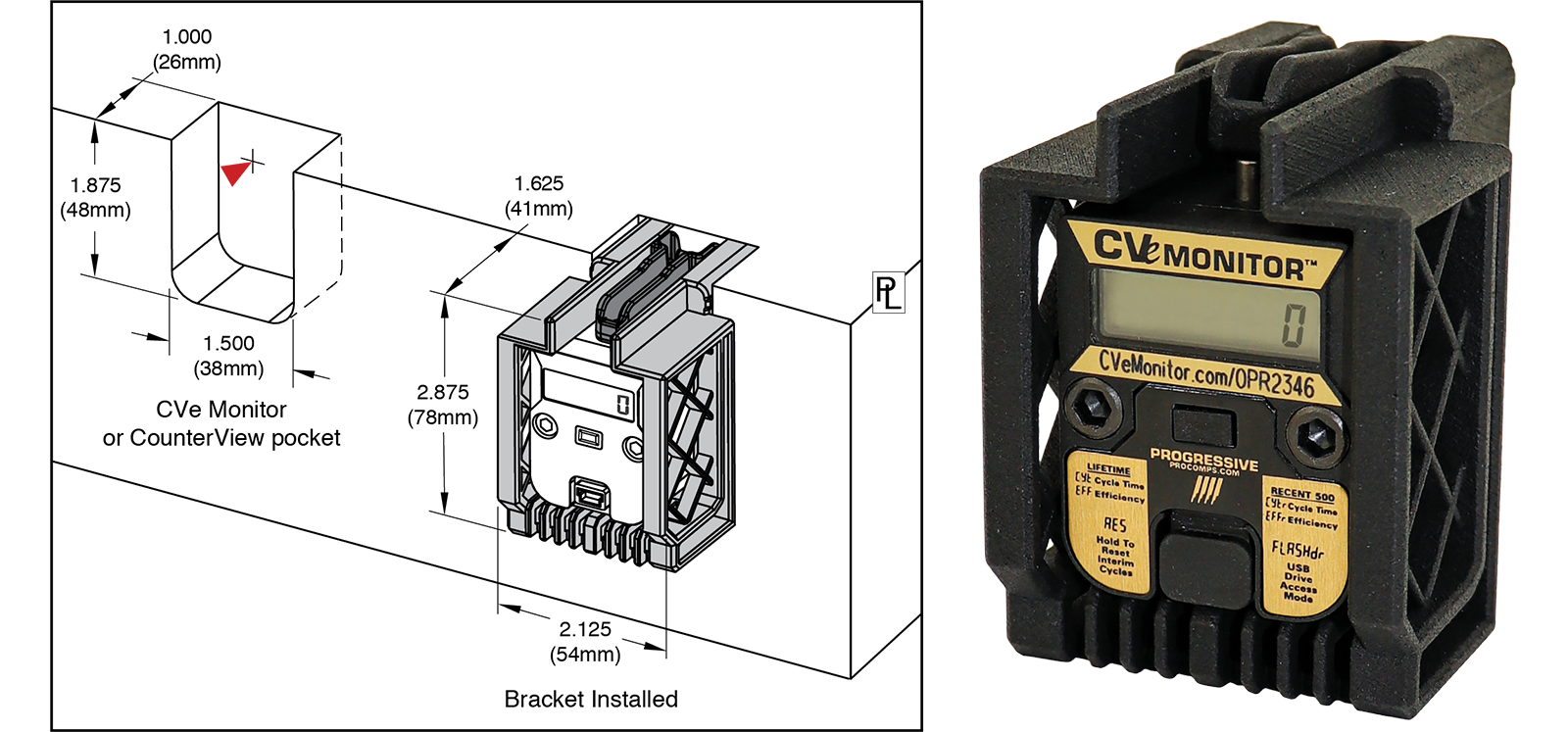

COUNTERVIEW: HIGH-TEMPERATURE

The new High-Temp CounterView offers the same functionality as Pro’s standard cycle counter with the added benefit of sustainability in higher temperature tools operating at a maximum of 375° F.

In addition, only Progressive offers counters in both left and right versions for mounting in either mold half for easy readability from the operator’s side, with Extension Rods for mounting away from the Parting Line’s heat.

INSULATOR BLOCK: EXTERNAL MOUNT

The exclusive Insulator Block is designed for tools molding high-temperature resins and allows Progressive’s CVe Monitor and CounterView to perform at temps up to 360° F.

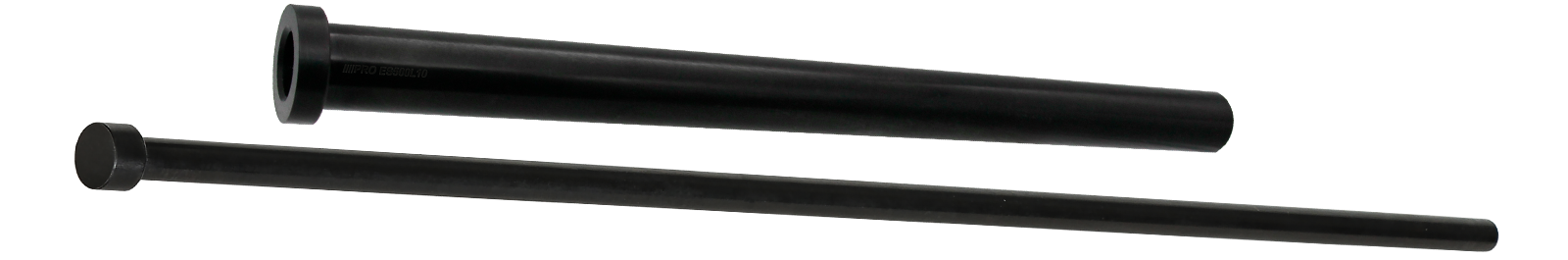

BLACK NITRIDE PINS AND SLEEVES

High temperatures can degrade many common greases. If a mold builder is unsure that a mold under warranty will be run with high-temp grease, Black Nitride Pins and Sleeves can be relied upon for running with little or no lubricants at all.

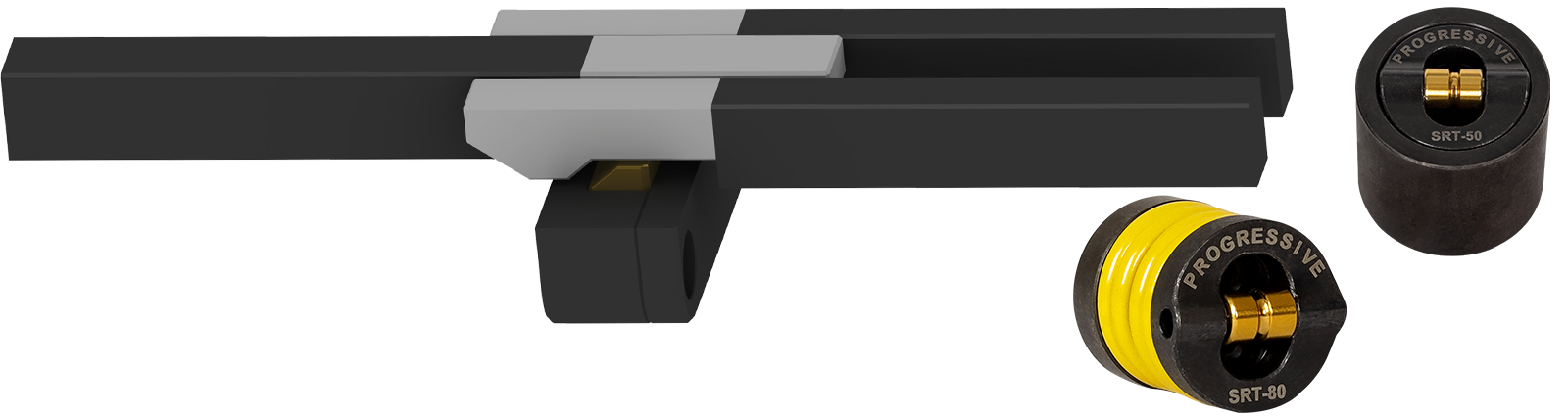

MOLD MECHANISMS

Hot molds frequently have plate sequencing and mold actions within them. Progressive’s Plate Locks can operate to 600° F, and SRT Slide Retainers perform up to 425° F.

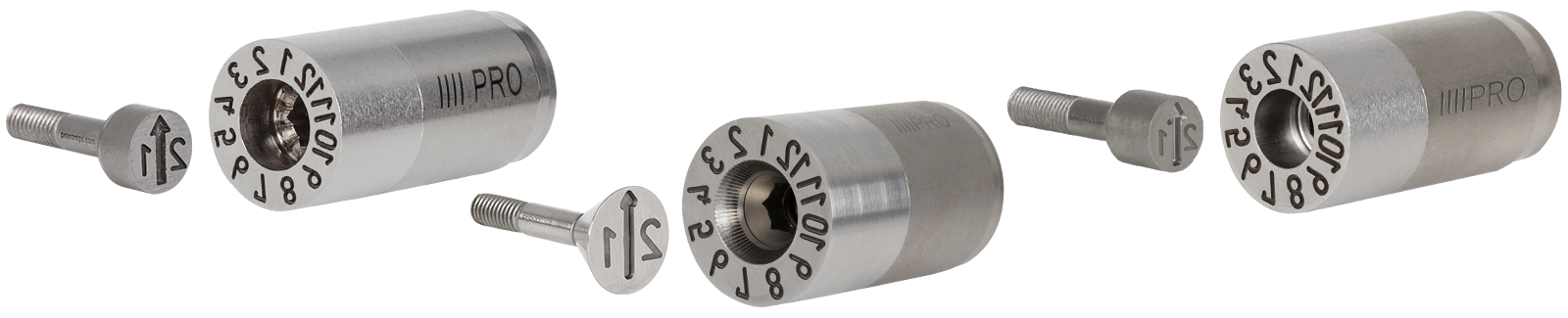

DATERS WITH HIGH-TEMP SPECS

Most Daters aren’t designed for high-temp operation, so for molds running up to 450° F, turn to Pro’s Locking Detent (DN Series), Remains Flush (RF Series), and Tapered Series (DTPR Series).

Additionally, the Tapered Series features a shut-off surface to prevent flash, even when running high MFI resins such as LSR, Nylon, and Medical-grade flex PVC.

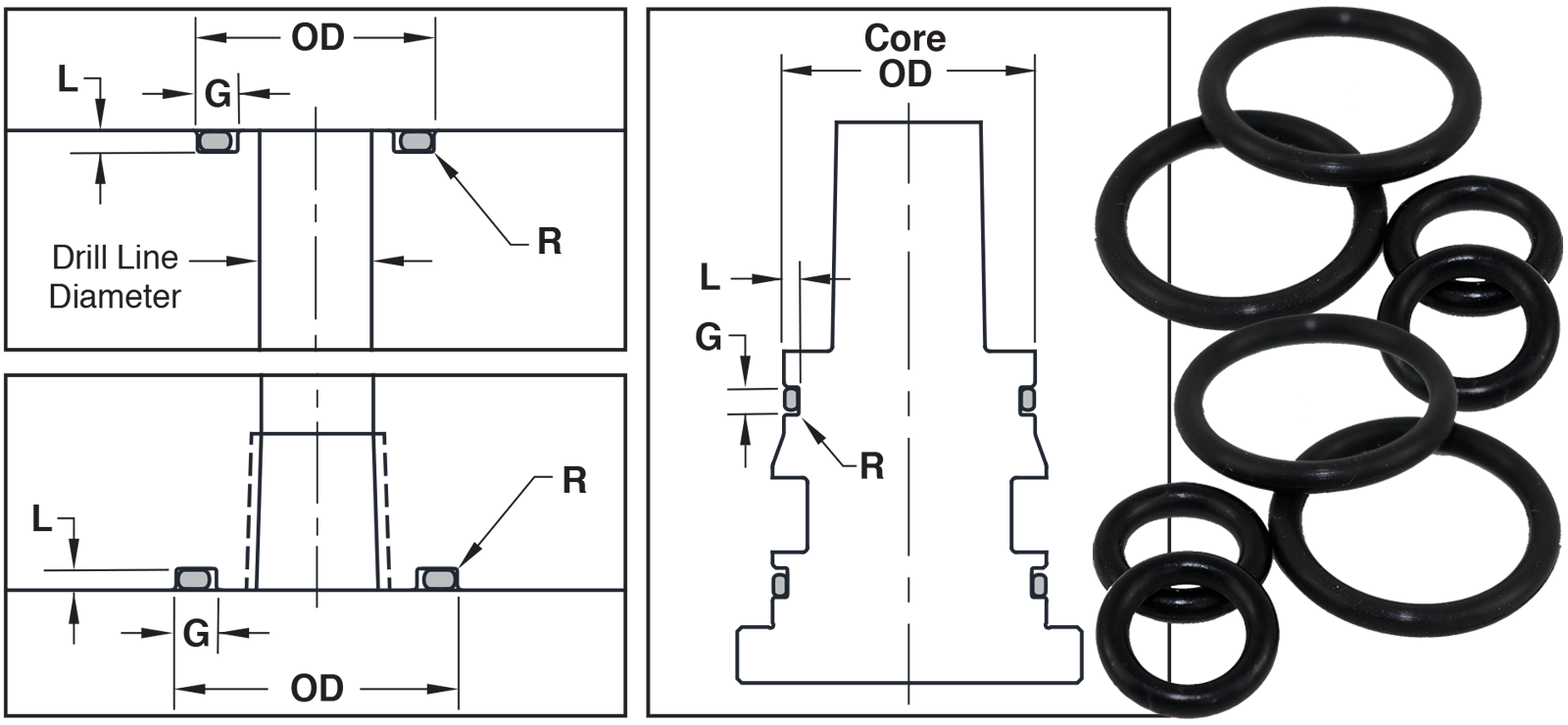

THREADLESS PLUGS

Often in 420SS inserts, tapping is avoided to not cause stresses and embrittlement that can lead to cracking.

For this specification, Progressive offers Push-in O-Ring Plugs, Tap-in O-Ring Plugs, and Threadless Diverting Plugs, all available with the “-V” option for Viton® for operating temps to 400° F.

O-RINGS

Progressive’s addition of O-Rings provides designers with CAD geometry that includes the machine groove detail and makes replacement downstream easier for mold maintenance personnel. O-Rings are available in two material options: Buna-N for temps up to 225° F, and Viton® for temps up to 400° F.

AROUND THE MOLD

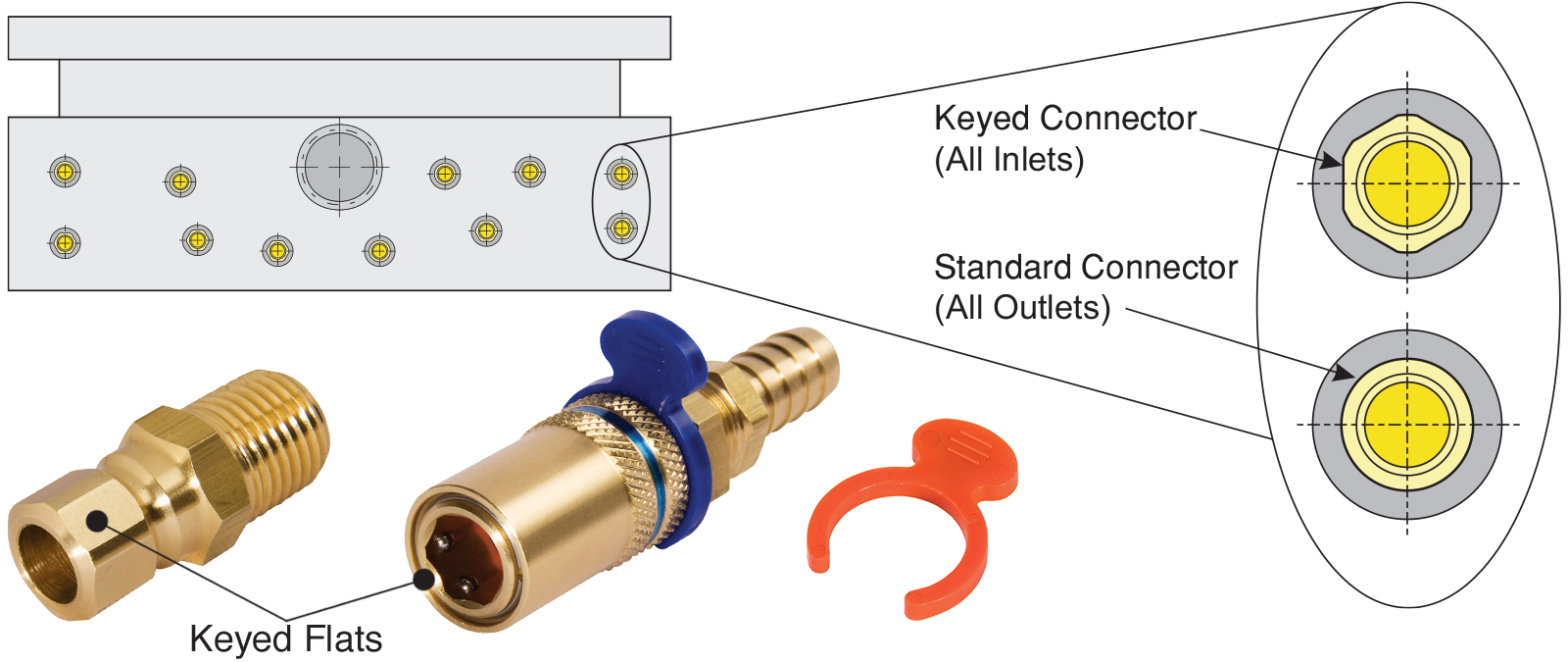

KEYED CONNECTORS

Improper connecting of lines on a hot mold could be detrimental to performance and part quality. Keyed connectors on the mold, combined with Keyed Socket Connectors with silicone seals that operate to 400° F, ensure safe and correct water or oil flow.

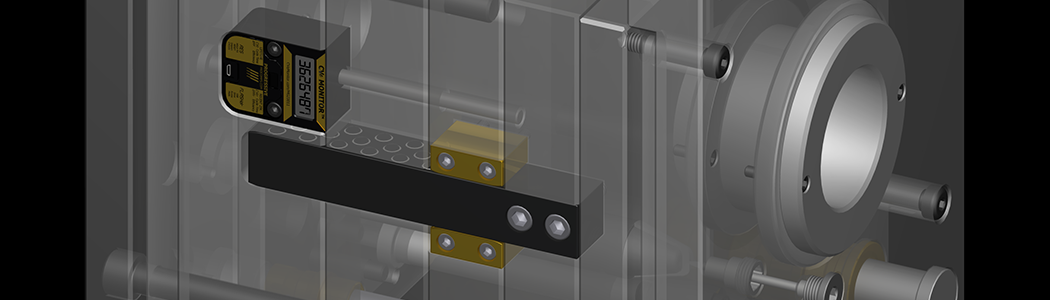

INSULATOR BLOCK: RETROFIT BRACKET

Insulator Blocks protect Progressive’s monitoring devices in high heat applications.

The new Retrofit Bracket installs within an existing pocket without any modification to the mold’s cavity or core half, allowing the CVe Monitor or CounterView to perform at temps up to 410° F.

THROUGHOUT THE PLANT

LOCKING SOCKET CONNECTORS

A hot mold hose that accidentally comes loose is hazardous. Locking Sockets are compatible with longtime standard connections, yet feature a twist to secure onto the connector with an operating temp of 400° F.

SETRAL GREASE

This premium synthetic mold grease is engineered for food grade and medical molding environments and is thermally stable to 570° F.

Progressive has worked to create a product line that is suited for the harshest conditions and the highest demands. If you’d like to drill deeper into any of these product specifications or discuss any other challenges that might be addressed with Pro standards, contact our Tech Team at 1-800-269-6653 or via email at tech@procomps.com.