New, cylindrical design adjusts for misaligned ejector plates.

Progressive’s UniLifter® was the first standard undercut release system when originally introduced in 1991, and throughout the years, the product line expanded. Now released is the C-Series UniLifter, a patent-pending design that offers new advantages for mold performance and easier mold assembly.

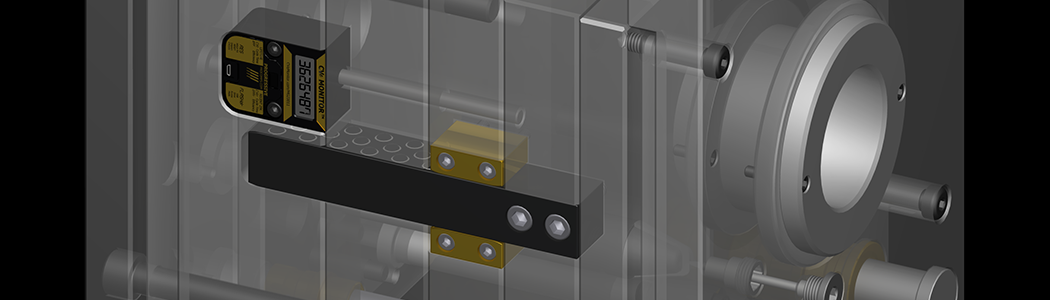

A mold’s ejector plates can sometimes become misaligned, putting stresses on ejection components. To compensate for this, the traditional UniLifter T-Gib has undergone a new redesign, with the coupling operating along a cylindrical C-Gib. This allows for rotational adjustment in the Y-axis, combining with rotational adjustment in the X-axis. Smooth travel along the cylindrical surfaces prevent stresses and wear between Core Blades and mold inserts.

The C-Gib’s cylindrical running fit provides smooth full contact operation while providing a surface against molding pressure versus the single point contact of dowel pins or tooling balls. For wear resistance, both the C-Coupling and C-Gib are Black Nitride treated, a lubricious high hardness treatment that can be run in greaseless, cleanroom conditions.

The C-Series UniLifter is fully compatible with the original UniLifter design. No change is required for mold designers or mold builders, and should a molder be experiencing ejector plates cycling out of alignment, the traditional Couplings and T-Gibs can be changed out to the new C-Couplings and C-Gibs that are at the exact same height, and therefore allowing the mold’s Core Blades to remain in use.

Also, with performance in mind, new S-7 Core Blades have been added to the range, allowing mold designers to select the best material, prehardened H-13 or hardened S-7 (54-56 HRC), for whichever insert tool steel has been selected.

To assist mold assembly, Progressive has developed a click-in-place feature that allows the toolmaker to set the Core Blade to the required operating angle and the C-Coupling to the travel start point of the C-Gib. Ejector systems are often crowded with various components, and this feature easily allows insertion of the assembly into the corresponding mold plate pocket without subassembly parts sliding out of position.

In addition to these changes, longer Core Blades have been added: MiniLifter Core Blades are now offered up to 18” and UL Series up to 20”. More T-Gibs have been added for additional travel, and Round Core Blades are now ion nitrided for extra wear resistance when used as lifter rods.

For more information, visit procomps.com/unilifters, call 1-800-269-6653, or email Progressive’s Engineering team at tech@procomps.com.