How Monitoring a Mold's Activity Helps Improve Performance

Moldmaking Technology Magazine Editorial Director, Christina Fuges, spent some time with Lorena Fisher, OEM Sales Manager for Progressive, who provided some strong motivations for monitoring molds, not the least of which is eliminating, or significantly reducing, unscheduled mold stoppages.

A transcript of the interview is provided below:

Christina Fuges: I’m Christina Fuges with MoldMaking Technology Magazine, and I’m here with Lorena Fisher of Progressive Components. Lorena, what is mold monitoring?

Lorena Fisher: Mold monitoring is establishing targets and maintaining those targets and being alerted when those parameters are not being met in order to prevent issues, prevent unscheduled mold stops, improve your performance of molds and monitoring your cycle time. Basically, it’s having a stable production environment when molding.

Fuges: What is the difference or why is it important to the different business types like an OEM, a molder, and a mold builder?

Fisher: They’re able to establish preventative maintenance suggestions and recommendations. They are also able to upload information that they’ll use during PPAPs and production; and they’re also able to qualify a mold warranty if they’re offering one. Mold monitoring, the goal is you don’t want unscheduled mold stops. You want to be prepared and stop the firefighting so you can work on continuous improvement. From an OEM standpoint, this is their asset. You know they want good parts. So, in order to have good parts they need a good mold running. A monitor will allow them to understand and give them data that their mold is being taken care of. You’re not spending time collecting it. You’re spending time working together on how to improve it.

Fuges: Progressive has the CVe OnDemand and CVe Live. How does one determine which is the best approach?

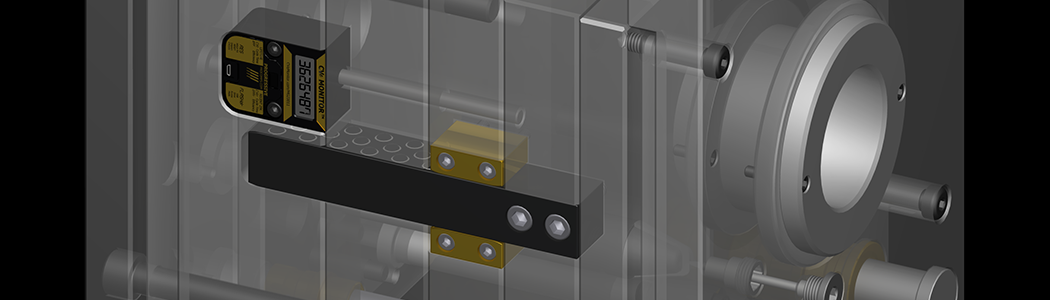

Fisher: CVe monitors come with the complimentary software OnDemand. That is a monitor that’s bolted on just like a mechanical counter, right in the same pocket, and that’s manual. You have to physically be there. You have to be pressing a button to get information or you’re plugging in via USB and downloading a report. CVe Live, on the other hand, is for customers that want to be able to monitor their production floor when they’re not there; real-time monitoring. They’re not looking at things, they’re not plugging in, they’re not downloading. They’re here at Amerimold walking the show learning about new technology, but they’re able to look at their phone and see “hey, are these molds running a cycle? Is this molding machine getting the preventative maintenance it needs?” And they’re able to give permissions and access to either suppliers or customers on that information at the same time, and they’re in control of it.

Fuges: Got it. Well, thank you, Lorena.

Fisher: It’s been a pleasure.