Check out these Progressive exclusive items designed to help streamline the manufacturing process.

Mold builders who manufacture their mold bases in-house, or purchase complex mold bases, are continually reviewing new products that can make the process more efficient. Progressive understands this and has exclusive items specifically for your priorities:

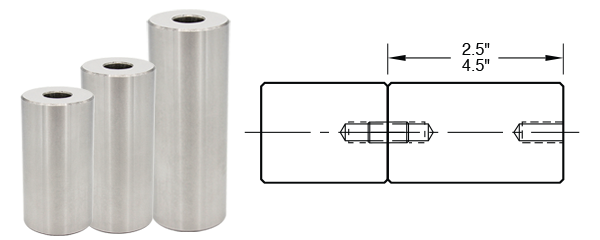

STAINLESS STEEL SUPPORT PILLARS

Medical molds often call for stainless support pillars. Progressive is the only supplier offering these as off-the-shelf items in 20 sizes, so there's no need to make in-house. In addition, for extremely large molds where a longer length is required, Pro's Stainless Steel Support Pillars can be stacked, as each 2.5" and 4.5" pillar is double-tapped for combining with another.

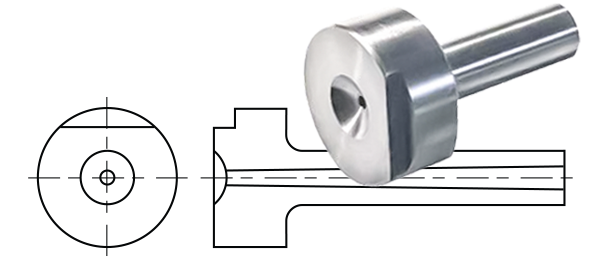

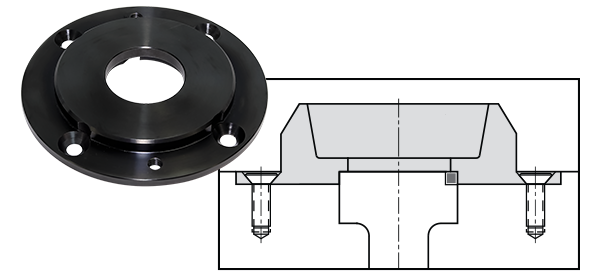

KEYED SPRUE BUSHINGS AND LOCATING RINGS

All of Progressive's Sprue Bushings contain a flat to eliminate the need to machine a dowel or counterbore for keying a sprue bushing. That flat corresponds with a key that is provided on each Locating Ring, so that no additional machining is required for the Top Clamp Plate.

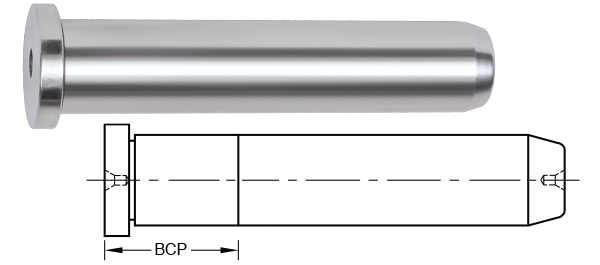

LEADER PINS PRESS FIT FOR BCP

For Guided Ejection, one shouldn't need to walk leader pins to a grinder to buzz down the press fit for the 7/8" or 1 3/8" Bottom Clamp Plate. Progressive offers an exclusive series of Guided Ejector Pins with the press fit ready for installation.

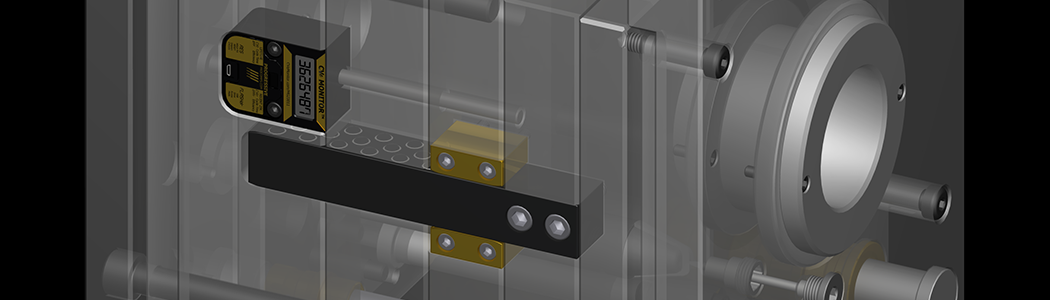

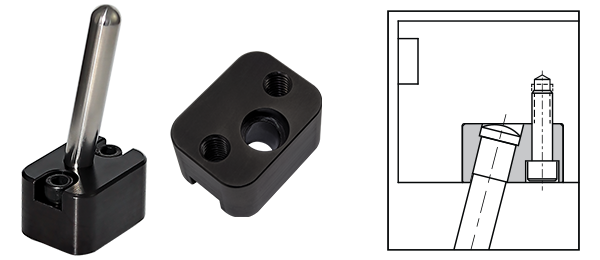

ELIMINATE LONG ANGLED BORES

Progressive’s exclusive Angle Pin Holders eliminate machining long, angled bores throughout the A-Plate. An added advantage downstream is that replacement from the parting line is possible for molders. With diameters from 3/8” – 3/4”, in 10°, 15°, or 20° angles, there’s likely one of our standard 42 sizes that will fit within a crowded mold base.

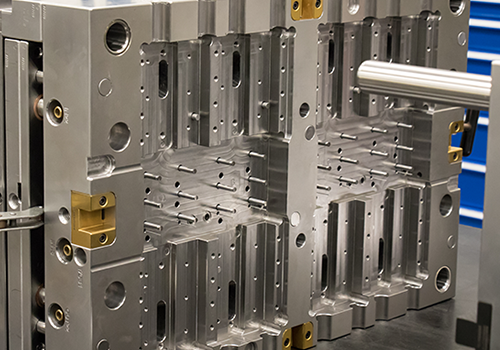

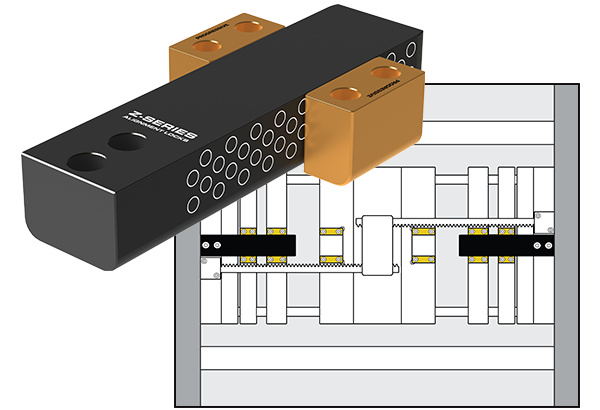

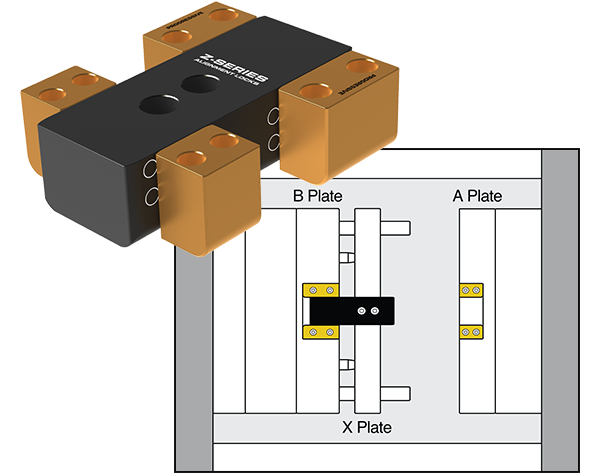

BAR LOCKS: SIDE OR TOP PREFERENCE?

Different shops have different machining preferences, depending on how they are set up. For this reason, Pro has added Top Machine Bar Locks, where your precision pockets are machined from the top and then tapped in the same setup as when machining for water line clearances and eyebolt holes. Also, for stripper plate molds, the new X-Style Bar Lock saves machine time and cost from the common practice of installing multiple Top Locks at both of the parting lines.

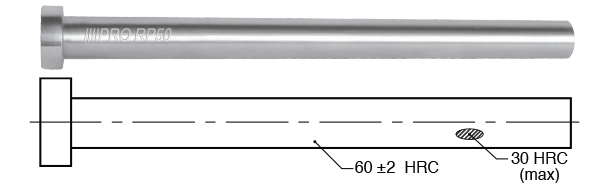

TAPPABLE RETURN PINS

Return pins are sometimes tapped, and it's no fun to machine others' 45-50 HRC core. Progressive's Return Pin surface is 60 HRC, but at the core, only 30 HRC for easy tapping.

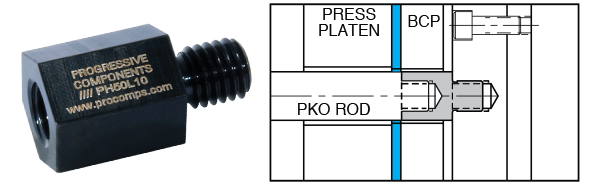

PKO EXTENSIONS FOR MOLDS WITH INSULATOR PLATES

When Pro first introduced PKO Extensions years back, it became a popular standard. Now, with more molds having insulator plates, 12 new PKO Extensions have been added that feature an additional .250" to reach further, eliminating the need to make custom PKO Extensions in-house.

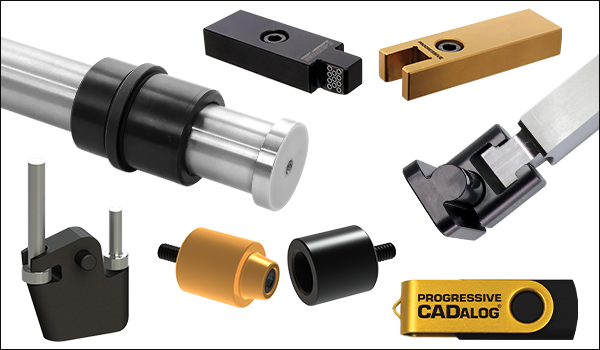

A Progressive advantage is that throughout the range of mold base Leader Pins, Bushings, and Alignment Locks, customers tell us that they find the consistency in sizing unmatched in the industry. This precision allows shop personnel to machine confidently to the numbers rather than double-check each component before each of the pockets and bores are machined.

In addition to the above mold base components, our new products can be viewed HERE, and our new v15 Catalog is available to receive HERE. Also, mold designers will appreciate the integrity of the geometry by receiving our CADalog®, offering multiple formats (SW, NX, VISI, Parasolid, ACIS, and IGES). Receiving the CADalog assures that you will receive notification of added geometry as we continue ahead to add more and more new products.

If you have any questions regarding any of our products or our CAD geometry please call 1-800-269-6653 or 1-847-487-1000, or click HERE to send an email inquiry.