EXCLUSIVES FROM PROGRESSIVE DELIVER ADVANTAGES FOR PRECISION TOOLING.

Located in the Northern Illinois medical molding corridor, Progressive's roots are in precise, critical-to-function tooling.

With that perspective, we continue to expand our product range with industry exclusives:

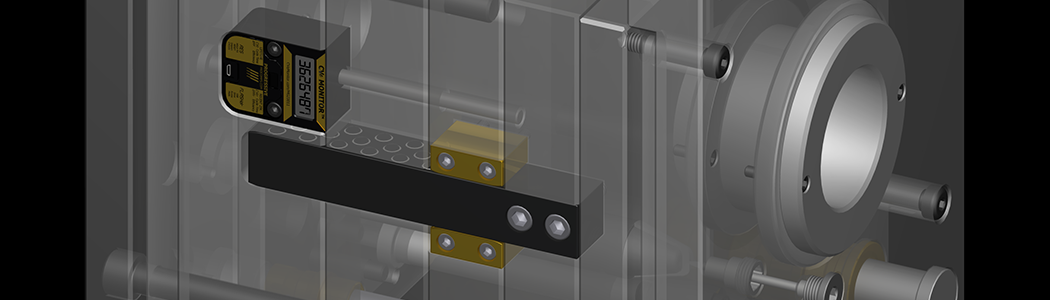

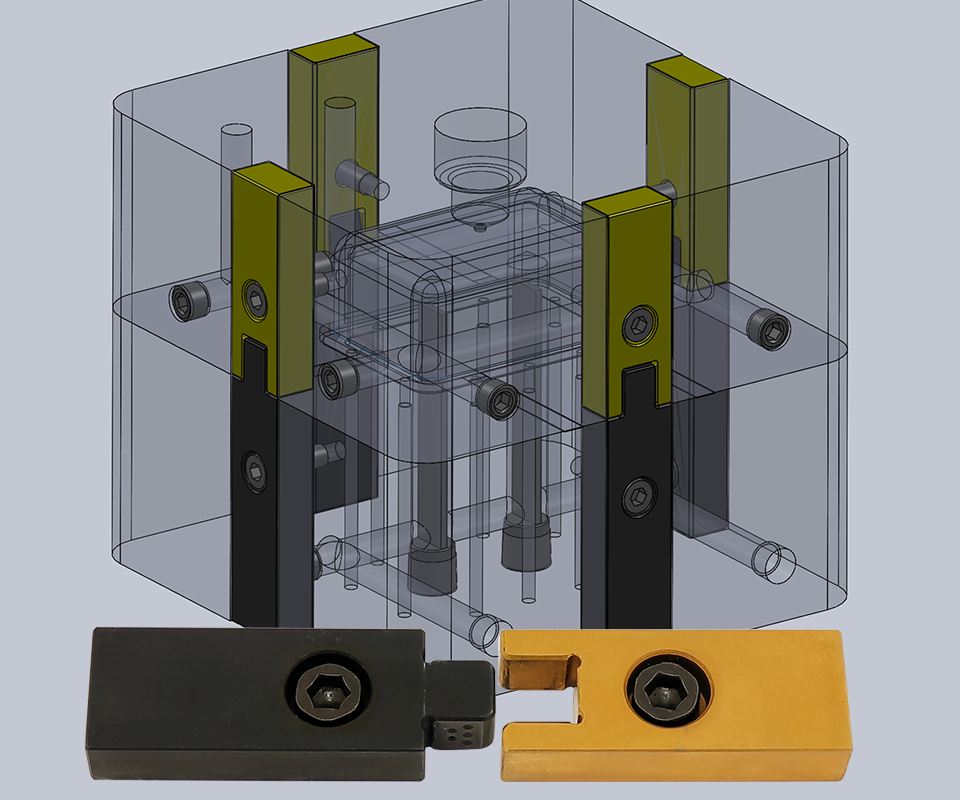

CAVITY INTERLOCKS

Progressive’s new Flat Series cavity interlocks are a space-saving design for mounting directly within a mold’s inserts. Overall lengths are sized for nominal plate thicknesses beginning at widths of only .625”, and lengths can be modified to suit the height of cavity and core inserts.

The Round Series offers the maximum amount of straight alignment engagement for the minimum amount of pocket depth required. Available in 1/4”, 3/8”, and 1/2” diameters, they can mount from the parting line to enable details to be located underneath or bolted from the back.

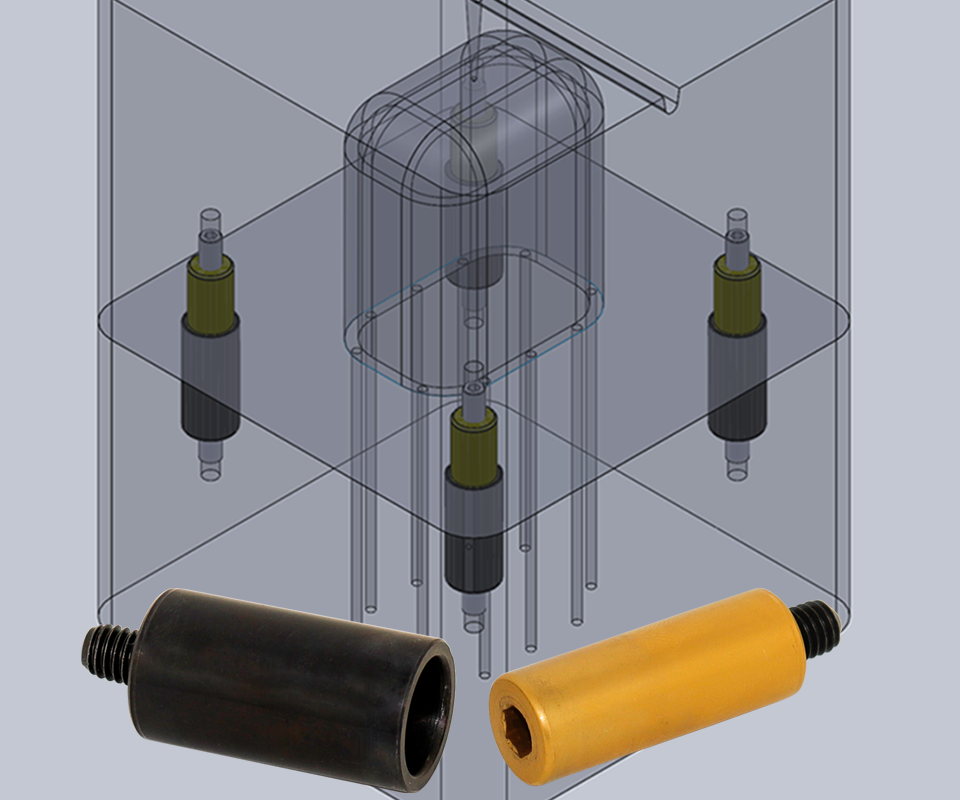

MINILIFTERS®

Pro’s new C-Series UniLifters feature hardened S-7 Mini Core Blades beginning at ¼” x 3/8” and are a proven, smooth-running system featuring Black Nitrided components that can even be run greaseless.

Need smaller? Lifter Blades begin at .070” thickness, and with their “up and then over” motion, undercut release along with ejection is assisted so as to not have small parts stick to the lifter. The core blade sits flush with the bushing at the molding surface, therefore no mismatches will be present on the part.

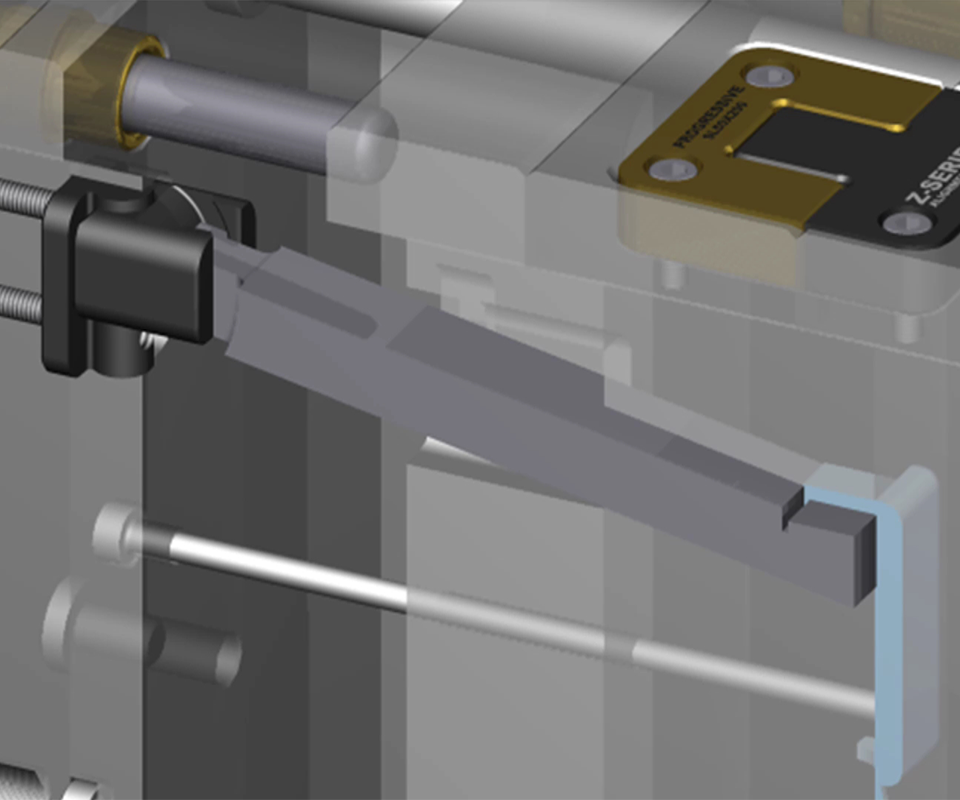

SMALL SLIDE COMPONENTS

CamActions® begin about the same size as ‘clothes pin’ retainers, yet at only 1” x 1” x 1 ¼” offer the complete modular mechanism. For just slide retention, SRT® Slide Retainers begin at .160” high and 5/8” diameter, small enough to be mounted to a ¼” wear plate.

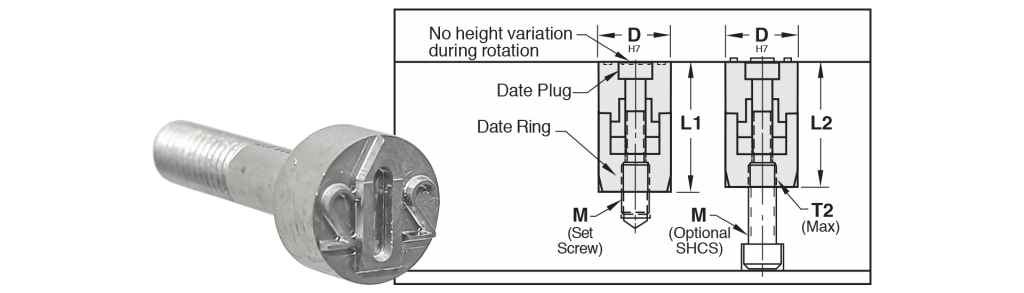

RAISED LETTERING DATE STAMPS

Often, every aspect is scrutinized when it comes to small, molded parts, including the appearance of how the date is marked. Progressive’s RF Series Daters (Remains Flush) offers traditional recessed lettering but also exclusive raised lettering. This enables the bottom of the molded part to have no indentations that, at times, can be questioned by QC Departments. This series also can be fastened from the front or back of the core insert.

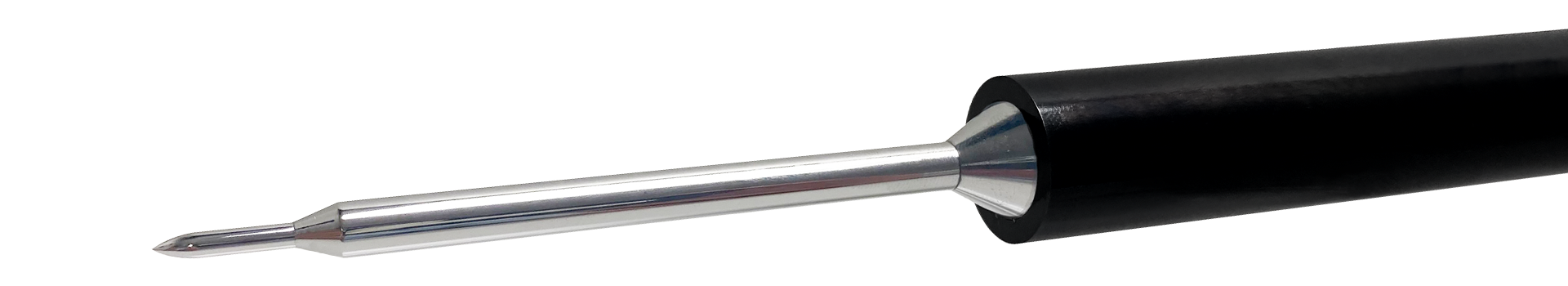

PRECISION THROUGH-HARDENED PINS

Moldmakers shouldn’t have to ‘inspect in quality’ by mic’ing pins during assembly, as customers report to us with Chinese pins in American brand boxes. Instead, it’s reported to us that Pro’s Ejector Pins are “like gages” in their consistent dimensional accuracy. Beginning at 1/32” diameter, click HERE for independent wear testing results versus others, and to request samples, click HERE if you’d like to check Pro’s pins head-to-head with your current source.

RAPID TOOLING INSERTS

Progressive’s RTI unit inserts are made in the USA. Ground flat and square with Leader Pin and Bushing locations precisely held, our A & B plates are interchangeable. Also, actual Leader Pins and Bronze Bushings (versus dowels and steel bushings) begin ½” diameter and provide accurate longevity.

Along with these components that we’ve engineered for small molds, molders are increasingly specifying Progressive’s Black Nitride Pins and Sleeves to be able to run greaseless without experiencing wear and flashing over time.

Whatever your design constraints may be, Progressive's Tech team is here to help! Call 1-800-269-6653 or send an email to tech@procomps.com.

We hope to make a big difference in your small tooling.