EXPANDED DIE CAST TOOLING COMPONENT LINE

Progressive Components is a leading supplier for the Die Cast Industry. With today’s designers and manufacturers increasingly looking for off-the-shelf, quality products for their tools, we are proud to announce the expansion our line of Die Cast Components, which have been engineered specifically, for the harsh conditions of the casting world.

Our new Ejector Pins, Locks, Leader Pins and Bushings are now Black Nitride for wear resistance, and we added more stainless steel cooling items that provide higher strength for improved safety and less deformation than brass.

This collection of advantages delivers convenience, unmatched tooling performance, and longevity for your tools. To access an online version of our new Die Cast Component Catalog, visit procomps.com/DCT. To request a printed version, please call 1-800-269-6653 or email us at customerservice@procomps.com.

MEET PROGRESSIVE’S DEDICATED DIE CAST TEAM

Progressive is the only American owned, independently operated full-line supplier of components and software for the die cast and molding industry.

We have three stocking locations in the US and six globally. Unlike our competitors, we do not have our products made in China, which ensures the highest quality steels and heat treatments possible.

While we’ve sold to die cast companies for nearly thirty years, we’ve recently formed a top-notch team to lead the focus on further advancing this area.

Contact anyone on our team, and you’ll find that we’ll work to assist you in reducing downtime and increasing the profitability of your company.

NEW DIE CAST COMPONENT ADDITIONS

We understand the importance of being able to access off-the-shelf, quality components for your tools. Our new Die Cast Tooling Component catalog features these new products and more:

- Proven to reduce the incidence of repair for stuck ejector pins.

- Black Nitride treatment reduces hole damage caused by galling.

- Core Pin hardness 50-55 HRC, comes complete with finished detail.

- The only side lock developed specifically for large Die Cast dies.

- Sized for deflection resistance.

- Large landing area offers improved part precision, reduces trimming.

- High strength Stainless Steel provides improved safety, and less deformation than brass.

- Designed to avoid collapse that chokes off flow with stainless steel.

- Specialized treatment outlasts conventional leader pins and bushings.

- Manufactured to withstand pressure of hard-to-align dies with diagonal thermal expansion.

ALIGN WITH THE LEADER

When producing tight tolerance parts for the automotive industry, Inland Die Casting Company knows that taking shortcuts today will lead to problems tomorrow.

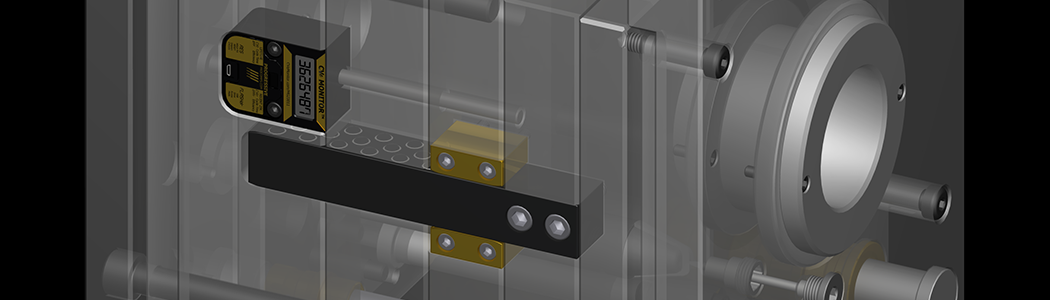

Progressive’s Inserted Bar Locks are designed to go the distance:

- Largest, standard alignment lock in the industry.

- Designed for mold weights from 25,000 to 75,000 lbs.

- Utilizes exclusive Z-Series technology for longevity.

Don’t let inferior components bench your tools. Align with the leading supplier of production tooling solutions — Progressive Components.

Call our Engineering team at 1-800-269-6653 / 1-847-487-1000 to discuss how the Progressive advantage can generate profits for you and visit us online at procomps.com/Z-Series to access test results, testimonials, catalog pages and more.

Oswaldo Roman from Inland Die Casting Company (pictured above), relies on Progressive’s Inserted Bar Locks to provide perfect alignment for his largest tools, which are designed to perform in harsh conditions.