REDUCE COSTS OF SPARES AND REPLACEMENTS

After trying various coatings and treatments on core pins that would wear on every run, Twin City Die Castings has found Black Nitride Core Pins to reduce the costs associated with downtime.

- Black Nitride treatment is a high hardness diffusion, which won’t wear like DLC and other surface coatings.

- Available on Ejector Pins, Core Pins, Ejector Sleeves, and Leader Pins, and Bushings as off-the-shelf standards.

Over the life of a die, the cost-of-ownership can become an immense expense and inconvenience. Progressive specializes in providing replacement components that stop the hemorrhage of dollars.

Call our Engineering team at 1-800-269-6653 / 1-847-487-1000 to discuss how these exclusive, profit-generating advantages can generate profits for you or click HERE for access to more info on our black nitride products.

ADVANCING STANDARDS THROUGHOUT THE YEAR

Progressive is proud to announce our v13 catalog release, which includes over 2000 new items to address needs across the tooling and molding world, along with a new version of our CADalog, a CAD Library for our entire range of products available as a downloadable file or USB drive.

Created by designers for designers, geometry is available in native SolidWorks, NX (MoldWizard and ReUse), and VISI, as well as Neutral .step, .x_t, .sat, and .igs formats.

INNOVATIONS FOR DIE CASTING

Black Nitride Pins and Sleeves

- Extend production runs with Black Nitride Ejector Pins and Sleeves, available as standards with competitive specials also offered

- Reduce failures caused by galling and soldering

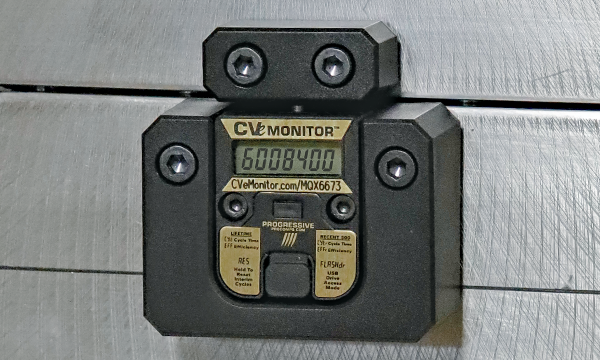

High-Temp CounterViews

- Exclusive new series that mounts on either half of the tool for easy viewing by the operator

- Designed for high temperature tools, the HT version operates at a maximum of 375° F (190°C)

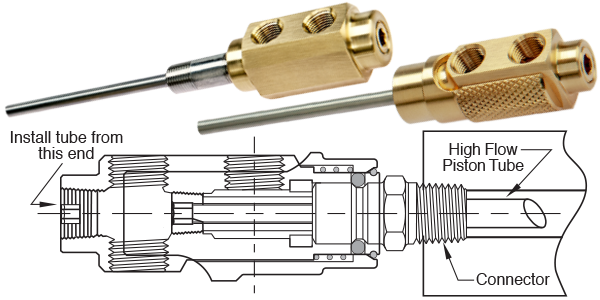

Cascades: Unique Options

- Rear Loading Cascades allow for easy access to Progressive’s High Flow Tube

- Quick and positive adjustment at assembly

- Select either brass or stainless steel

- Also available in a Coupler series, allowing installation and removal without disconnecting cooling lines

Insulator Block

- Protects Progressive’s monitoring devices in high heat applications

- Installation can occur on either half of the tool

- Insulator Block allows the CVe Monitor or CounterView to perform at temps up to 360°F (180°C)

RhinoFeet and RhinoToes

- RhinoFeet™ are a simple, safe, and efficient solution for elevating and storing heavy items within the shop, eliminating hazards associated with wood and skids strewn about the plant

- RhinoToes™ are designed to help correctly position plates to avoid pinch points during assembly

ProFile Asset Management System

- Designed to streamline the organization of molds, dies, fixtures, and end-of-arm tooling, ProFile, a cloud-based system stores tool data, documents, photos, set-up sheets, and GPS locations

- A standalone approach, or share data with your current ERP system

- Several Asset Tag and Plate options are available off-the-shelf, or order custom units