Unmatched Performance

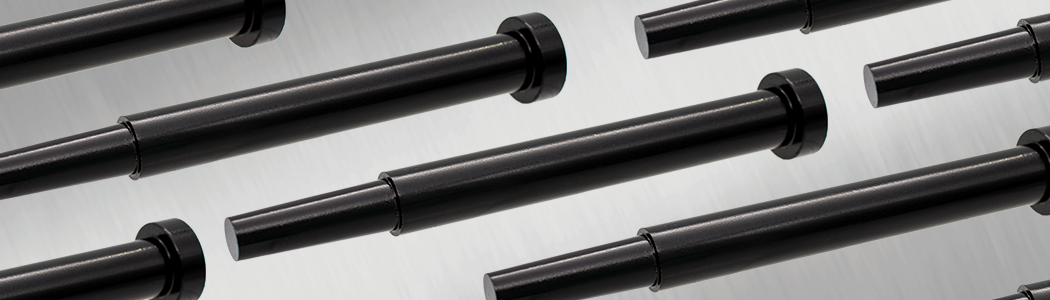

Black Nitride products from Progressive are proven to perform in medical cleanroom molding environments, cosmetic / appearance product production, harsh conditions such as die casting, and beyond.

Black Nitride (BN) is diffused .003”-.005” into the component, and is not an additive process that can wear off and end up in your parts, like DLC and other surface coatings.

~ Jim Kepler, President, Intertech Plastics

~ Dan Sheridan, Twin City Die Castings

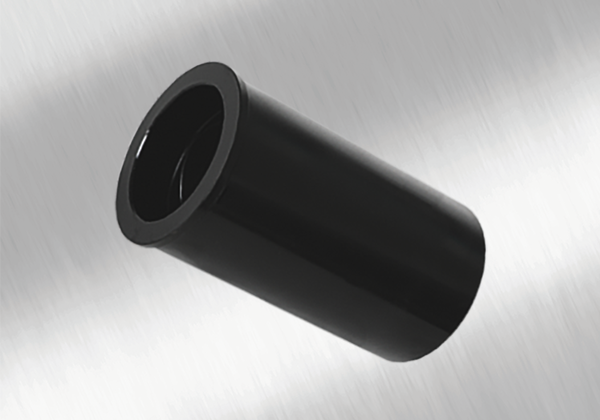

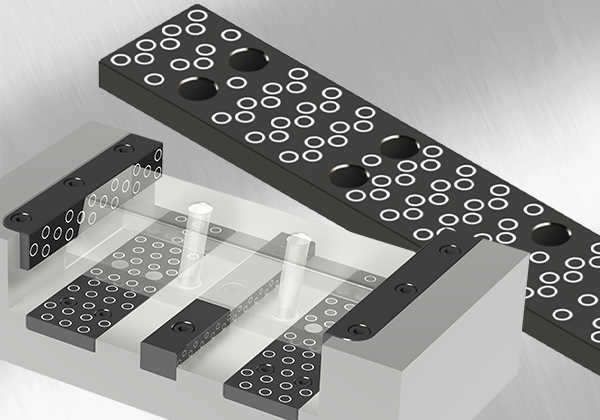

New Greaseless ejector Sleeves

To expand its offering of Ejector Sleeves, Progressive has added treatments for greaseless applications.

Black Nitride Ejector Sleeves have a precision honed lubricious surface that does not require grease in cleanroom applications, and a high hardness (66-70 HRC) that is suited for harsh conditions such as with die casting.

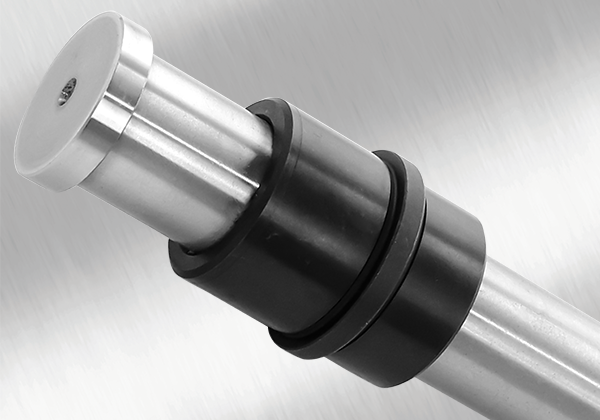

“When the BN Series Sleeves are combined with Progressive’s Through-Hard Ejector Pins, the dimensional specifications provide the industry’s closest combined precision fit and tolerance between pin and sleeve,” states Glenn Starkey, Progressive’s President. “Unlike PVD processes such as diamond-like coatings (DLC), black nitride penetrates the steel’s substrate and won’t chip, flake, or peel.”

AS FEATURED IN mOLDMAKING TECHNOLOGY MAGAZINE

Case Study: Twin City Die Castings Co.

PROBLEM: Die soldering during casting process was degrading core pin surfaces, which required cleaning three to four times per shift, and

replacement every month.

SOLUTION: Switch to black nitride custom core pins from Progressive Components.

RESULTS: Cleaning was reduced, replacement intervals extended five times thanks to greater longevity gained from using black nitride products.

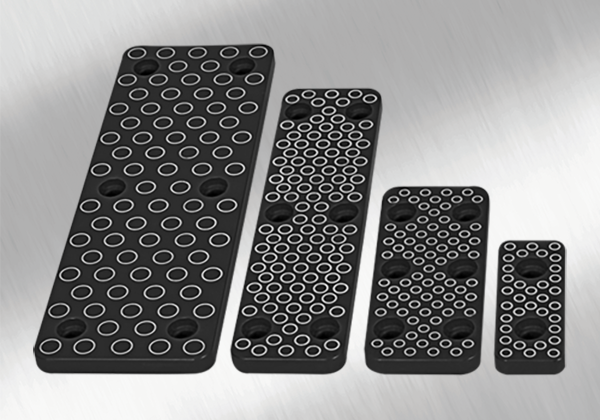

Black Nitride Products

- Black Nitride treatment reduces hole damage caused by galling.

- Proven to reduce the incidence of repair for stuck ejector pins.

- Precision honed lubricious surface that does not require grease.

- High hardness of 66-70 HRC that is suited for harsh conditions.

- Black Nitride treatment reduces hole damage caused by galling.

- Core Pin hardness 50-55 HRC, comes complete with finished detail.

- Specialized treatment outlasts conventional leader pins.

- Greaseless for medical and durable enough for Die Casters.

- Specialized treatment outlasts conventional bushings.

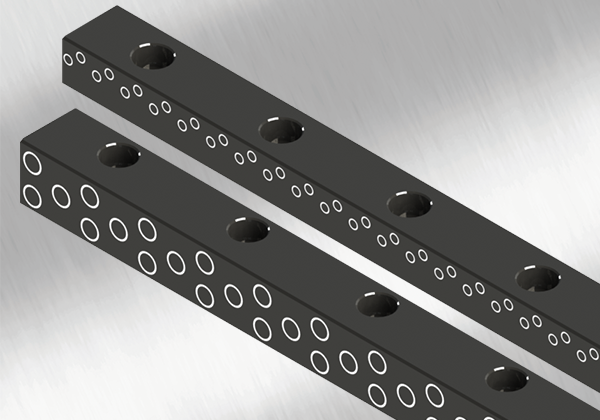

- Manufactured to withstand pressure of hard-to-align dies with diagonal thermal expansion.

- Available as a standard item in sizes from 1/2″ diameter to 2″ diameter.

- Proven to provide improved performance for greaseless medical environments and durability for Die Casters.

- Designed to be cut-to-length for each slide’s required length.

- Available off-the-shelf with pre-machined counterbores for SHCS and offered in six standard sizes with a range of lengths from 2” to 13.5” long.

- Designed to be cut-to-length for each slide’s required length.

- Provided flat and including final fitting stock, Wear Strips are available in eight standard inch sizes, with a range of lengths from 6″ to 13.5″ long.

- Superior wear resistance with particle rings for lubrication retention.

- Standards sizes eliminates the need to manufacture in-house.

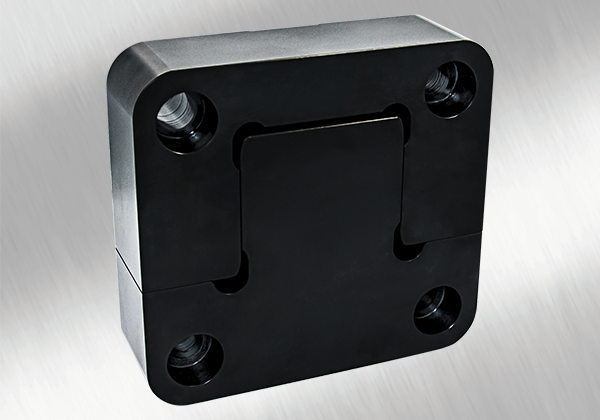

- Largest standard lock in the industry, sized for deflection resistance.

- Large landing area offers improved part precision, reduces trimming.

For questions and more information on our Black Nitride offering: